Mercedes-Benz Custom Tailored Trucks and the customised-truck workshop in Molsheim.

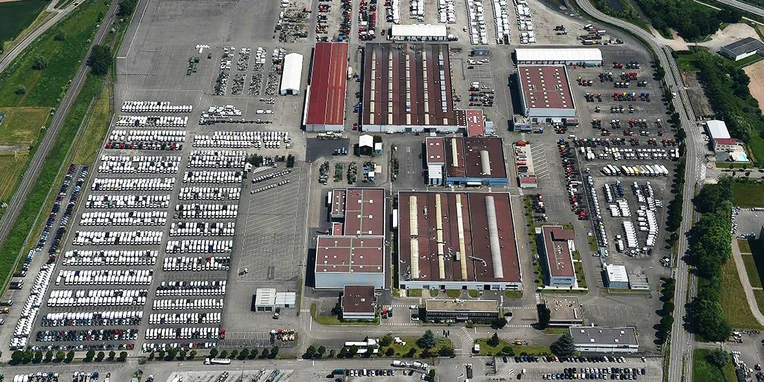

Mercedes-Benz Trucks Molsheim and Custom Tailored Trucks (CTT) are based just a few kilometres from Strasbourg in Molsheim in Alsace, France. This unique site specialises in three business areas. These include the conversion of commercial vehicles for specific customer requirements, as well as the production of vehicle parts (laser cutting, bending, pressing, welding and painting), and finally the assembly of UNIMOG cabs. Concentrated expertise in Mercedes-Benz quality – all centred around a common value, the symbolic Mercedes-Benz star.

A shared site for various corporate structures.

From customer advice to the development and production of vehicle parts and vehicle conversion, the 700 employees at the Mercedes-Benz Trucks site in Molsheim work hand in hand every day to deliver tailor-made solutions. The plant covers an area of 50,000 m² with 76 processing stations and 6 spraying booths.

In organisational terms, Custom Tailored Trucks (CTT) is linked to the Mercedes-Benz Special Trucks business unit in Wörth,where around 1,000 employees produce 3,500 Econic, Unimog and Zetros vehicles each year. Since its founding in 2000, CTT has developed and produced more than 260,000 vehicles representing almost 30,000 assembled axles, 8,000 m of shortened wheelbases and around 30,000 m of extended wheelbases – all with a single goal: to fulfil the needs of customers the world over.

In demand worldwide: the right vehicle for every situation.

Whether on European transit routes or in the most remote regions on Earth: CTT trucks are being used in over 140 countries around the world. This makes Mercedes-Benz CTT the largest truck converter in the world.

Whether for China, Brazil, New Zealand, the Middle East, Switzerland or Europe: all vehicles that are individually converted by CTT according to customer requirements meet strict Mercedes-Benz standards and quality. This quality promise also applies to customer service and spare parts, which are all available through Mercedes-Benz’s worldwide dealer network.

From heavy-duty tractors to oilfield carriers.

Whether it’s a long-haulage, delivery or construction site vehicle – a Mercedes-Benz truck can adapt to any situation. In an increasingly complex world, however, vehicles may lack some options that would be necessary for developing an ideal vehicle, despite the wide variety offered in the series-production catalogue.

Custom Tailored Trucks (CTT) steps into action here to offer tailor-made, specific solutions. Recognised for its expertise, CTT is the preferred point of contact when it comes to the accompanied production of vehicles to meet each customer’s specific requirements. Conversions are made at CTT true to the motto: "Trucks you can trust".

Depending on the type of conversion at CTT, series-production trucks are transported from the series production plant in Wörth to the conversion plant in Molsheim. As one example, four-axle oilfield vehicles destined for China pass through the Alsace production facilities in order to be converted there and, among other things, to extend their wheelbase. For this purpose, the components installed in the frame and the rear axles are removed so that the side members can be cut before welding in the extension and reinforcements.

Thanks to the modified wheelbase, the drive shaft as well as cables and lines must also be extended. At the same time, further modifications must be undertaken, such as relocating the fuel tank or battery box.

Based on the diversity and complexity of the processes, workshop staff are also highly qualified. Despite the tailored production process, CTT uses the same production system from Daimler Trucks as is used everywhere else. This means that all conversions are subject to the same quality checks as the series-production vehicles. In addition, each step is carefully recorded in the IT system to properly document the entire manufacturing process for each vehicle.

Further examples of conversions by CTT:

- Increased payload: conversion from 4x4 to 6x4/4 with pneumatic suspension

- Cab conversion: larger cab (double crew cab) for emergency services vehicles, roof cut-outs for refrigerated vehicles, etc.

- Chassis adjustments: chassis reinforcements, additional radiators etc., for heavy-duty vehicles (up to 250 t).