Steerable axle for the trailer.

Goegl made the semitrailer with a stake body specially for applications on the steep mountainsides in the forests, where the paths snake up and down. It is equipped with a steered axle so that it runs precisely in the Unimog's track. A sensor on the fifth-wheel kingpin, which engages in the fifth-wheel coupling, measures the steering movement of the towing vehicle and passes on the data calculated directly to the trailer axle, from where the turning angle is transferred to the wheels. The trailer's steering control can also be operated manually via radio remote control, which has considerable advantages when manoeuvring. The reversing camera plus an additional camera for monitoring the implements round off the equipment. Various work lights ensure additional safety when working with the crane..

Wood chips are produced from the residual wood from the sawmill and the carpentry. The second semitrailer with a 25 m roll-off container and tandem axle is used for transportation. Here, too, both axles are fitted with automatic steering. The 20-tonne hook from Palfinger for the pulley is mounted directly on the trailer.

Project implemented with Unimog general distributor partner:

Auer GmbH

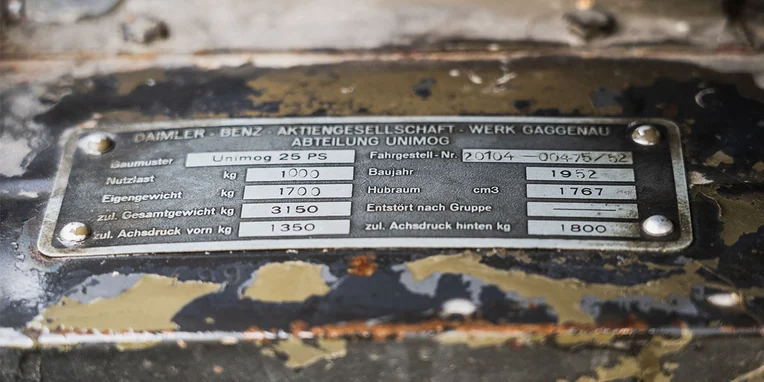

Unimog from the year 1952.

The family also owns a Unimog built in 1952. Patriarch of the family Alois Thurner took it on when it was withdrawn from service from the Swiss army, complete with all the original equipment. Since then he has been proudly visiting classic vehicle meets with his gem.