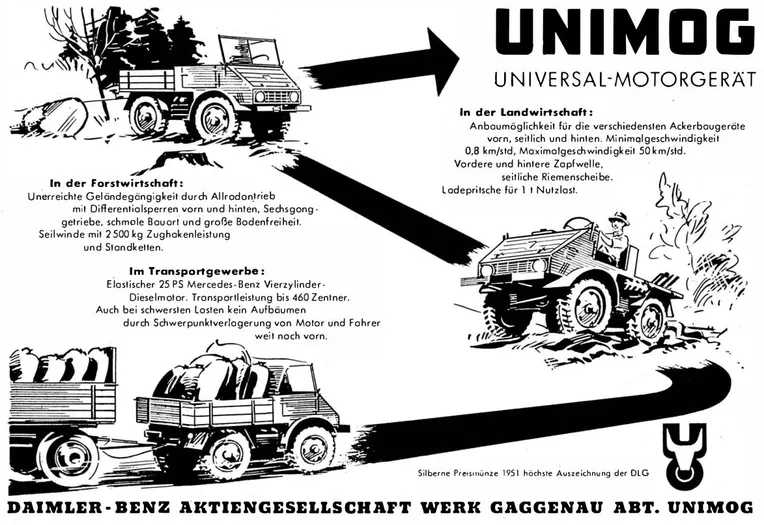

1946–1955 | The Unimog – the initial years and the first successful models.

For 75 years now the Unimog has stood for efficiency, flexibility and legendary off-road capabilities like no other vehicle. Resourceful engineers whose goal was to make the best possible use of the Unimog vehicle's versatility laid the foundation for this success story.

The birth of the Unimog.

Albert Friedrich is one of the Unimog vehicle's founding fathers. Immediately after World War II the former head of Daimler-Benz aircraft engine production recognised the enormous need that small and mid-sized companies working in Germany's agricultural sector had for tractors. In addition to off-road capabilities, there was great demand for a vehicle that was simple to convert for a range of very different tasks.

From 1946 a dedicated team headed by the engineers Albert Friedrich, Heinrich Rößler and Hans Zabel developed and tested the first prototypes for such a commercial vehicle on the premises of Erhard & Söhne. It was Hans Zabel who took the somewhat cumbersome project name "Universal-Motor-Gerät für Landwirtschaft" (Universally applicable motorised machine for agriculture) and created the succinct abbreviation "Unimog".

The Boehringer Unimog goes into production.

By the end of the development phase the team had created a vehicle with all-wheel drive, differential locks and portal axles which met all the demands regarding transport volume and tractive force but was still capable of driving 50 km/h. In addition implements could be fitted on all sides – a clear advantage when compared with the classic tractor to which implements could only be attached at the rear. The engine was a Daimler-Benz OM 636, a robust diesel engine which guaranteed cost-efficient operation.

In 1948 the Unimog was presented to a professional audience for the first time at the trade fair in Frankfurt organised by the German Agricultural society. There the response to the vehicle was very positive, not least due to its impressive driving characteristics both on the road and in difficult terrain, its easy operation and great versatility. That year, the Unimog also went into series production for the first time at the Boehringer factory in Göppingen which had already delivered cast parts for the prototypes.

The hallmark of the very first 70200 model series, of which around 600 vehicles were built, was the ox-head logo. Today there are still around 120 of those Boehringer Unimog – and many of them are still in operati

Gaggenau becomes home to the Unimog.

As demand for the Unimog grew, not just in Germany but increasingly abroad too, production capacity at the Boehringer factory was soon insufficient. A take-over agreement was signed with Daimler-Benz and in 1951 production began in the truck plant at Gaggenau. The vehicle was still sold under the name "Unimog 25 PS" and with only small modifications to its design it was possible to produce considerably more Unimog from the new 2010 model series thanks to more rational production processes. Thus in the first seven months of 1951 just over 1000 Unimog were produced in Gaggenau.

Improved power take-offs opened up the possibility of new applications in the forestry industry and in field work. Suddenly work that had previously required many hands could be done by one person. Very quickly further areas of operation were discovered for the Unimog as a support vehicle in the fire service or in road construction.