Extreme off-road Unimog for Germany’s largest open-cast mine.

It is the quintessential man’s man playground: the Hambach open-cast mine in the Rhine lignite mining region. Four gigantic lignite excavators extract up to 40 million tonnes of coal from this site every year. This requires robust, specialist mining machines – like the newest member of the fleet at the largest German open-cast lignite mine operated by RWE Power AG: a Unimog U 4023 ambulance (RTW). Because in the event of an emergency, fast help must be guaranteed – from the highest to lowest levels of the pit, over extreme terrain, in all weathers and where no other vehicle on four wheels can go.

Regularly on the move.

When handing over the vehicle to his colleagues from the rescue station, Sascha Funk, who is responsible for vehicle procurement, remarked: „May this Unimog clock up as little mileage as possible!“ Ideally no emergency deployments will be necessary. However, it is still vital to drive the vehicle around on a regular basis. This is because the open-cast mine changes its appearance almost every day. And rescue teams must always keep their bearings.

Proof of confidence for the Unimog.

RWE has used Unimogs for four decades and has almost 130 units in permanent use throughout the Group. „The extreme off-road Unimog RTW is the ideal vehicle for the really tough conditions we face in open-cast mining“, says Sascha Funk. In contrast, conventional RTWs based on the Mercedes-Benz Sprinter, which RWE also uses in its rescue service fleets, are suitable for fast overland journeys.

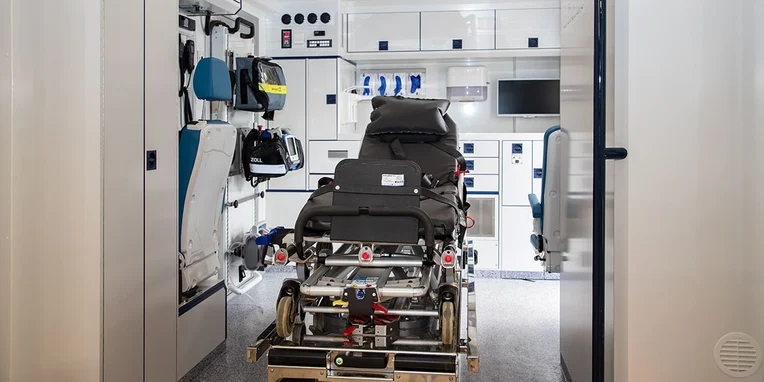

The U 4023 in Signal White with an air-conditioned Emmert van body is by no means standard: the patient stretcher extends two and a half metres out of the van body and is lowered to the ground by a hydraulic/pneumatic system. So it is perfect for recovery tasks. Defibrillator, cooling and warming drawers, vacuum immobilisation mattress, oxygen supply – all medical devices can be conveniently removed from outside the vehicle using a retractable rail system.