An important step.

"From the sketch to the finished vehicle, from the prototype to the production truck – now the time has come: with the eEconic, we are putting the first electrically powered and series-produced Mercedes-Benz Special Truck on the road", says a delighted Dr. Ralf Forcher, Head of Mercedes-Benz Special Trucks. "The exchange with our customers has shown: cities and municipalities want CO2-neutral vehicles for their fleets. Especially with regard to large cities, there is a need for quiet, clean and safe logistics and waste disposal solutions. And we offer just the right truck for this."

Especially with regard to large cities, there is a need for quiet, clean and safe logistics and waste disposal solutions. And we offer just the right truck for this.

Dr. Ralf Forcher, Head of Mercedes-Benz Special Trucks

Dr. Andreas Bachhofer, Head of Production and Plant Manager at the Wörth plant adds: "In the fall of 2021, we were giving the go-ahead for series production of our electric trucks here at the Wörth plant with the eActros, and now we're following up with the eEconic. This is made possible by our flexible production and our highly motivated team at the site, which has integrated the eEconic into line production in a very short time and is working hand in hand to meet the high quality demands of our customers. The start of production of the second electric truck here in Wörth shows once again that we are already in the middle of the transformation to new drive systems at the site."

Series production of electric trucks at the Future Truck Center.

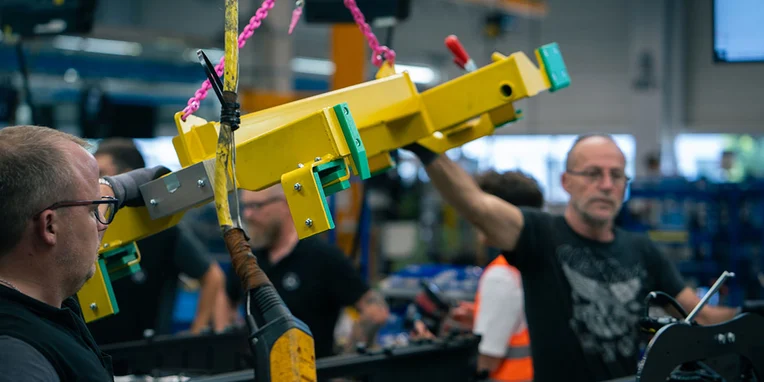

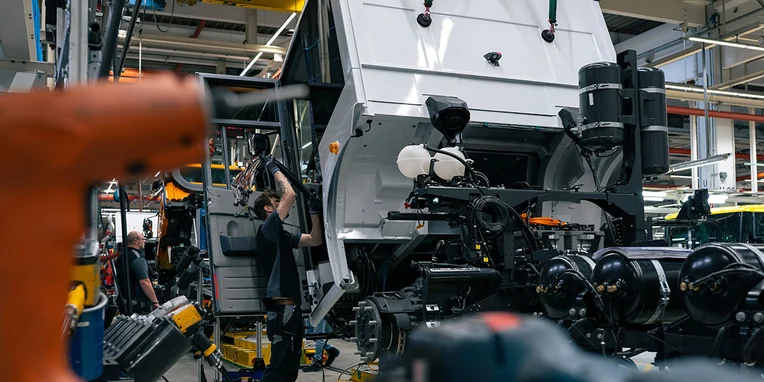

The eEconic will be manufactured in the existing Mercedes-Benz Special Trucks assembly line, in parallel and flexibly alongside the trucks that will be powered by internal combustion engines. "So the eEconic and the Econic are manufactured on the same production line", explains product manager Linda Fritzenwanker. "But once the vehicle is built, the eEconic goes to the Future Truck Center for electrification."

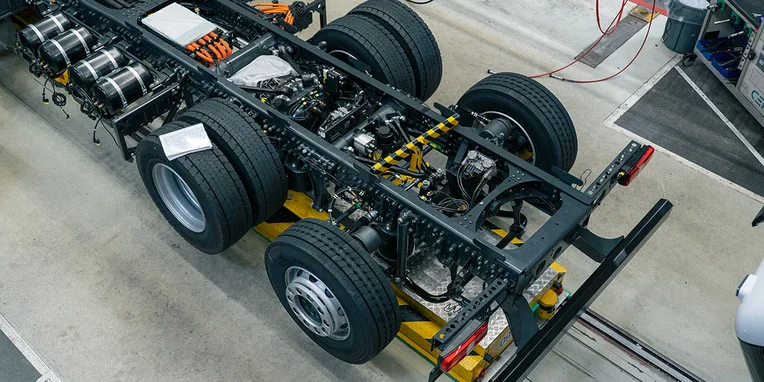

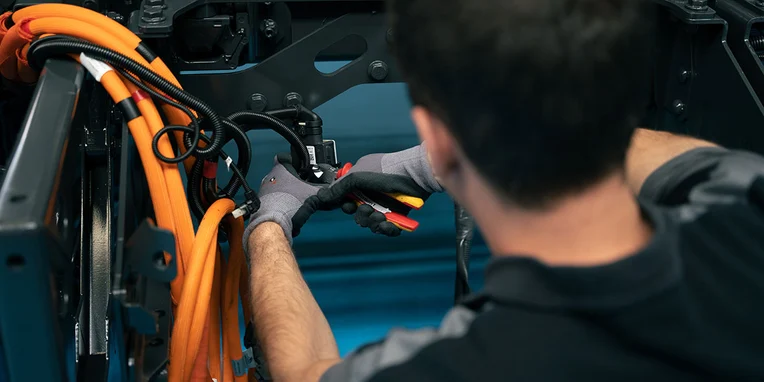

There the Special Truck – just like the eActros – it is equipped with the electric drive components. In several production steps, the high-voltage batteries and the charging unit are installed, among other things. Once all high-voltage components have been assembled, the entire system can be put into operation and the truck is ready to drive.

High-voltage tasks.

In the course of the transformation towards CO2-neutral transport, the Wörth site has set itself the goal, among other things, of continuously developing its workforce for the production of trucks with new drive systems. This also includes ensuring that employees who work on high-voltage vehicles such as the eEconic undergo specific training and development. Since 2018, employees at the Wörth site have been qualified for the production of electric trucks. To date, around 2,700 employees have been trained to handle high-voltage vehicles and components at the site's own training center. They have thus acquired the necessary knowledge and are optimally prepared for the new requirements in production.