High pulling power even in wet weather.

The Unimog U 423 with their 170 kW (231 hp) 4-cylinder engines have to pull towed weights of up to 600 t in daily shunting operations. The Unimog's torque converter clutch, which is available ex works, ensures wear-free moving off and increased starting torque.

And this also works reliably in bad weather and on wet rails. Because thanks to all-wheel drive and differential locks as well as the higher permissible gross vehicle weight of the new Unimog generation, traction is maintained even on slippery tracks – an important safety factor, especially when braking.

Perfectly equipped for shunting.

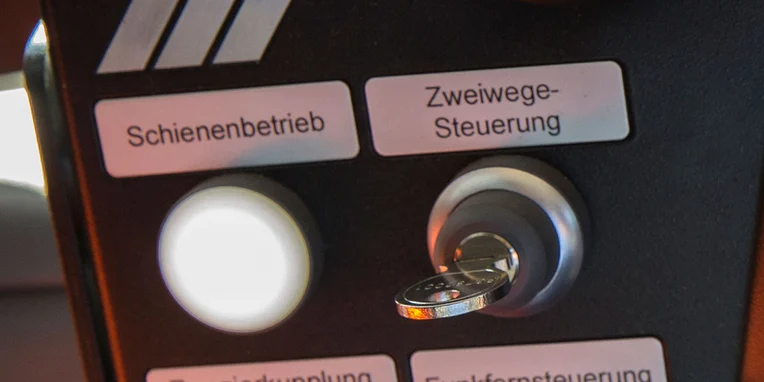

The equipment of the two Unimog U 423 includes sophisticated railway technology from the specialised body manufacturers Zagro and Zwiehoff. For example, the two powerful shunting experts have a wagon braking system for 800 t and coupling bars at the front and rear. Practical radio remote control enables precise shunting manoeuvres, while the driver can keep an eye on the wagons outside the vehicle.

For in-plant use, the Unimog is approved according to BOA (construction and operating regulations for connecting railways). As a flexible alternative to shunting locomotives, the road/rail Unimog vehicles are a familiar sight at the Mercedes-Benz plant in Bremen. Advantages include the quick switch from rail to road, the economical operation and the simple integration into the existing infrastructure. Ralf Menger sums up by saying that a comparatively inflexible locomotive would simply no longer be able cope with the workload on the existing railway infrastructure. The Daimler-produced commercial vehicle assistance is therefore a real boon and ensures that many more new cars will leave Bremen destined for Mercedes-Benz customers all over the world.

The Mercedes-Benz plant in Bremen.

More than 12,500 Mercedes-Benz employees currently produce ten passenger car models at the Bremen site, including the C-Class, GLC, SLC and the SL. In 2017 more than 420,000 vehicles rolled off the production lines. This means that the site is one of the largest Mercedes-Benz passenger car plants.

The Bremen site is also well equipped for the future: from 2019 the first electric vehicle of the new EQ product brand will be built there. By the end of the decade all newly developed intelligent drives will be built in Bremen – from the conventional combustion engine to plug-in hybrids and fuel cell vehicles.

You're interested in the Unimog implement carrier?

View product information