The powerful professional for professionals.

Complete jobs more quickly and under high cost pressure: cities and communities, service providers and contractors all have to cope with a great variety of challenges. And then the Mercedes-Benz Unimog turns up at just the right time: The specialist for municipal work can be used perfectly to capacity for up to 365 days a year – for jobs such as mowing, mulching, tree and brush control, winter services, sweeping, cleaning – or even for carrying loads and transporting goods.

And it more than pays for itself. Through a combination of performance and efficiency, it guarantees that life cycle costs are kept extremely low. Its numerous innovative features also make the Unimog safe, ergonomic and productive – and thus one of the most coveted work places in your community, public works or company.

Applications

in winter service.

The Unimog implement carrier is fully committed to combating snow and ice.

The onset of winter, lightning, snow storms: winter service requires uncompromising, reliable models – just like the Mercedes-Benz Unimog. That's because, in addition to summer mowing, clearing snow is counted among its prime activities. Thanks to its permanent all-wheel drive, differential locks and single tyres, with snow chains as optional extras, as well as the powerful mechanical and hydraulic drives, the Unimog is able to combat difficult road conditions in winter.

All-round visibility.

The camera monitor system features up to three optional cameras. The two main advantages of the system are an optimised overall view and, at the same time, easier attachment of implements. The cameras are integrated at the front of the vehicle and at the rear. A freely positionable implement camera is also available. The image is displayed on a monitor in the cab interior.

Reliable corrosion protection.

Repels salt and salt solutions: corrosion protection. As the absolute professional in winter service operations, the Unimog is very well equipped to deal with aggressive road salt. Its drivetrain and chassis, as well as all other parts that come into contact with de-icing agents, have been protected effectively against corrosion.

Ready for ploughing.

In addition to many other practical functions, the Unimog’s high level of specialisation in winter service deployment demonstrates one particular detail: for work with snow ploughs in particular, the hydraulic system in the Unimog has a snow plough relief at its disposal which transfers part of the weight to the front axle. This increases the traction and driving stability of the vehicle and reduces wear and tear on both road surface and snow plough.

Applications

Green space maintenance

A cut above the rest: mowing, mulching, brush and tree control with the Unimog.

After the winter comes the mowing season: verges and hedges lining the roads have to be cut regularly to keep them well maintained. These mowing and mulching operations are another main sphere of action for the Unimog. Its high axle loads make it possible to attach one, two or – if a rear-mounted mower boom is used – even three mowers. This means that the implement carrier pays for itself throughout the year. The fully proportional working hydraulics ensure excellent and precise control movements during implement control. Another major benefit: EasyDrive synergetic traction drive This system makes it easy to switch between hydrostatic driving when working and driving with a manual gearbox without having to stop. Supplemented by the improved AutomaticShift for Unimog U 435 and U 535, this increases productivity and safety, especially when used on rural roads and motorways.

Mowing door, rotating seat and mowing mirror.

Mowing operations with the triple-mowing combination and a two-man crew are especially productive. The mowing door with rotating co-driver's seat is specially equipped for this purpose. It guarantees the best view of the working area.

Also available as a retrofit solution.

Vario-Pilot® transferable steering system.

To provide the best simultaneous view of the road and working area, the Unimog has the option of being equipped with the practical VarioPilot® transferable steering system. This allows the driver to change seating position to the other side of the vehicle, depending on the type of work that is being carried out.

In combination with the optional glass mowing door, users have a perfect view of the implements when mowing or maintaining roadside verges.

Right-hand/left-hand variable steering:

- Changing of the steering wheel position including instrument panel and pedals in under 30 s

- The best seating position for any job

- Assists with one-person operation and improves efficiency, especially for operations like mowing and sweeping

Fast and easy cleaning of the cooling system.

The cooling system and component arrangement ensure the cooling of all units, even when ambient temperatures are high, driving speeds low and jobs exceedingly dirt-intensive. Cleaning of the radiator is also very easy: simply open the grille and blow the filter clean with the compressed air pistol. The radiator can also be cleaned automatically – with the optional reversing fan (reversing the airflow) which features multi-timer interval control.

Applications

for cleaning.

A clean performance with the Unimog.

Cleaning dirt from squares and roads, keeping construction sites clean, special cleaning for crash barriers or tunnels – the fight against dirty conditions is never complete. But, the Unimog is up to the challenge. With a variety of attachments and mounted implements, such as front-mounted or body-mounted sweeping machines, high-pressure cleaning arms or tunnel washers, the professional implement carrier is capable of cleaning every corner of public spaces and works yards. Changing implements quickly also means that several different implements can be used during one shift.

From motorway roadworks to inner cities.

The Unimog has the answer to various cleaning requirements. Front sweepers, for instance, keep construction zones clean, high-pressure cleaning arms remove dust and dirt from the whole surface quickly and effectively and special implements like tunnel washers replace a whole fleet of special vehicles. With a pre-installation for mounted sweeping units available ex works, even a mounted sweeper can be assembled and disassembled in the shortest possible time. The Unimog is quickly ready for other tasks.

Applications

Transport.

Makes light work of heavy tasks.

Compared with conventional transport HGVs, the Unimog implement carrier is extremely versatile – but no less efficient. On the contrary: with a front loader, the Unimog can load its own trailer and thus carry out the work of two vehicles. As a crane vehicle, the Unimog can be used universally, including on construction sites. Advantages such as compact dimensions, high payloads and its off-road capability take it almost anywhere.

Compact and suitable for off-road use.

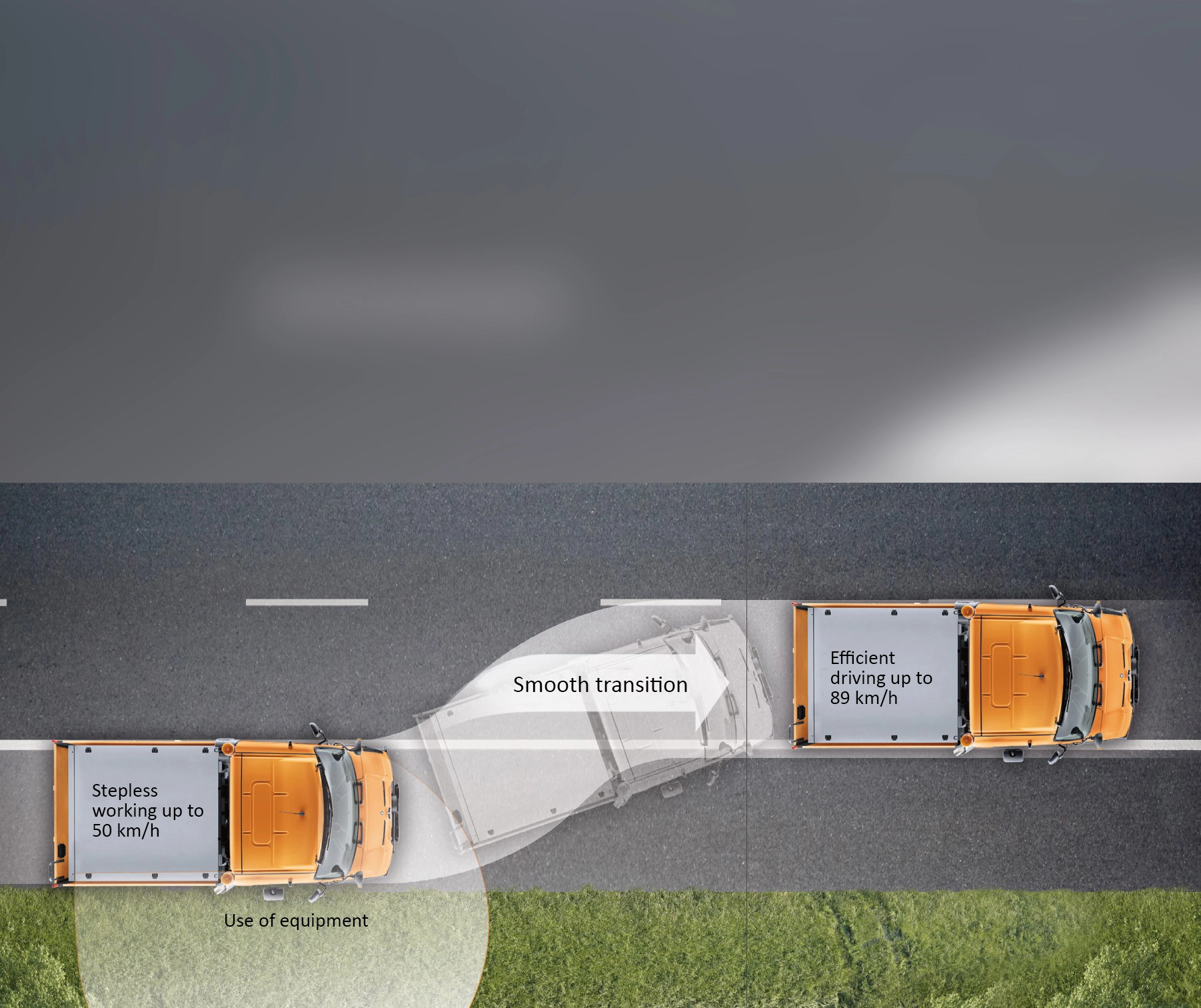

With its compact dimensions, the Unimog can make the most of its great capabilities in the tight spaces found on construction sites. And it never has to give up on soft, unpaved ground. Back on the road, the vehicle's high payload is a bonus. The modern and fuel-efficient common-rail engines with 4 or 6 cylinders delivering up to 260 kW (354 hp) drive it to maximum performance on transport routes: on roads, the Unimog reaches speeds of 89 km/h (legally regulated) and thus reaches distant destinations quickly and reliably, even when towing low-loaders with heavy loads.

Powerful performance.

Outstanding implement-carrying features and similarly strong and efficient common-rail engines make the Unimog a genuine transport professional. When fitted with a front loader it can load the trailer it has brought along itself; unload construction materials in confined areas and transport low-loader trailers with heavy loads over great distances.

Product benefits

Vehicle concept.

The Unimog puts in efficient performance just about everywhere it goes.

Its basis is its characteristically sturdy and versatile chassis, together with its hydraulic and mechanical implement drives and its compact dimensions. These give it a small turning circle and a short front-end assembly which is a great advantage when working with front-mounted implements. Here, the Unimog is also able to demonstrate its outstanding advanced system solutions: Thanks to intensive cooperation with bodybuilders and implement manufacturers, the Unimog is the ultimate specialist for a wide range of applications. This diversity ensures high capacity utilisation throughout the year. Other advantages become apparent as part of long-distance journeys: the Unimog can reach speeds of up to 89 km/h and is licensed for motorway use.

Outstandingly versatile on the job.

- Four attachment and body areas:

Attachment areas at the front of the vehicle (with standardised front mounting plate, e.g. for a shredder), on the side and at the rear of the vehicle. A platform body or shredder can, for instance, be mounted behind the cab. - Standardised mechanical, hydraulic and electrical interfaces

- Mechanical implement drives:

Front and rear power take-off shafts - Hydraulic implement drives and control:

VarioPower working and power hydraulics®

Legendary chassis expertise.

- Permanent all-wheel drive

- Large axle articulation and differential locks

in both axles - Drop-centre axles

for high ground clearance - Single tyres and coil springs

for maximum driving comfort - High axle loads,

e.g. for heavy front attachments - Efficient common-rail diesel engines with 4 or 6 cylinders,

from 140 to 260 kW (190 to 354 hp)

Product benefits

Ergonomic cab.

A good working atmosphere improves productivity.

Effortless control of every application: a comfortable cab and intuitive operating concept. The Unimog was built to achieve great things. That is why it provides well-considered and productive workplaces for the driver and up to two crew members. The spacious cab and the even cab floor ensure plenty of head and leg room for occupants. The effective damping of vibrations and the seating position behind the front axle further contribute to fatigue-free working. The innovative operating concept provides genuine relief during the working day. The elements are arranged so that they can be reached easily. A modular switch panel is located in the centre console and the assignment of the switches can be adapted as required.

Advantages that pay off in the long run.

1 Multifunction steering wheel

2 EasyDrive lever

3 Instrument cluster with 12.4" display

4 Stalk lever

5 Multifunction joystick

6 Intuitive operating concept

7 Modern and ergonomic interior

8 Panoramic cab with good visibility of front-mounted implements and traffic

9 Powerful air-conditioning system

Comfort steering.

At slow speeds, steering usually requires more force. Comfort steering in the Unimog reduces steering forces at low speeds and when stationary thanks to electromotive power steering. This takes the strain off the driver and is particularly advantageous when working with heavy front attachments or large-volume tyres.

Multifunction display and steering wheel with Easy-Drive lever.

Important functions in the operating menu, such as changing the settings for the hydraulics system, can be altered using the buttons on the steering wheel – without having to take your eyes off the work area. The parameters selected appear on the colour TFT display in the instrument cluster. The EasyDrive lever is positioned on the left behind the steering wheel. Here, drivers are able to use their left hand to change the direction of travel, shift the gears and operate cruise control in both the hydrostatic and mechanical transmission modes, thus leaving their right hand free for such tasks as positioning implements using the multifunction joystick.

Easy-Drive.

The innovative EasyDrive traction drive brings together the advantages of a fuel-efficient manual transmission and a stepless hydrostatic traction drive. It allows swift changes between the two drive types. The hydrostatic drive itself has two driving modes: work mode for jobs requiring a constant engine speed and drive mode for stepless acceleration with a variable engine speed. Despite the divergent functions, it is easy to use: with the EasyDrive lever on the left behind the steering wheel, users can control the direction of travel, the selected gear and cruise control. Alternatively they can use the multifunction joystick or the accelerator pedal and brake, depending on the job at hand or the driver's preference.

Sensitive and powerful: the hydraulic system.

The working hydraulics system is outstanding thanks to its high hydraulic output, which makes it possible to make swifter implement positioning movements. The optional load-sensing hydraulics (110 l/min) draw only the amount of output actually required. VarioPower power hydraulics consist of two circuits, both with a maximum hydraulic oil flow rate of 125 l per minute, 280 bar pressure and a top performance of 58 kW. Yet, its operation is extremely simple: All settings are displayed in the new instrument cluster.

Operate implements simply and intuitively: the multifunction joystick.

The speed with which tasks can be completed depends to a great extent on how the implement is operated. Here too, the Unimog sets standards. The removable joystick is used for basic functions like raising/lowering and swivelling to the left or right as well as for controlling many other functions. These include Electronic Quick Reverse, the working speed, the display of the text menu in the multifunction display or the snowplough relief.

Product benefits

Safety.

With the Unimog, you always have a good overall view.

The panoramic cab of the Unimog makes an effective contribution to preventing accidents as it provides a very broad field of vision in conjunction with a short front-end assembly and thus minimises blind spots. This increases safety, particularly in conditions with poor visibility, such as at night as well as in rain or during the winter months. With its active and passive safety systems, Unimog users and other road users alike are kept well protected.

Active and passive safety systems.

Perfect overview and high safety standards: As a state-of-the-art commercial vehicle, the Unimog makes no compromises when it comes to safety. With its active and passive safety systems, Unimog users and other road users alike are kept well protected. The most important features are: outstanding view to the front thanks to the short front-end assembly and the panoramic cab, headlights with daytime running lights, great directional stability and ABS as well as seats with integrated three-point seat belts and headrests.

Safe workplace: the tested cab.

The Unimog meets high safety standards, such as the ECE-R29/3 standard, an internationally recognised proof of strength for the survival space of all occupants in commercial vehicles, or the flame/flammability test in accordance with the Hazard Protection Regulation FMVSS 571.302. Furthermore, the roll-over performance of the Unimog complies with the OECD Standard Code 6.

Panoramic cab and short distance from implement to axle centre.

The front-end dimensions and the position of the driver are especially important when working with front-mounted implements. The Unimog falls below the legal standard limit of 3.5 m, even with implements. That means that other road users appear in the driver's line of vision much earlier – especially in confusing situations such as turning off at a narrow intersection.

Product benefits

Economy.

In use 365 days of the year: the high utilisation of the Unimog saves you money.

The Unimog implement carrier has more than earned its reputation as a grafter. It performs at its best all year round in a wide range of road maintenance applications. And in addition, it can be used for many other different applications. To ensure this is the case, Mercedes-Benz has been cooperating closely for decades with international implement manufacturers and bodybuilders to create the best conditions for customised system solutions.

Shorter downtime.

Low maintenance costs and long service intervals. Despite the complex technologies used, the Unimog still manages to lower maintenance costs – for instance thanks to intervals of 1400 operating hours. In addition, the front PTO shaft, hydrostatic drive and power hydraulics are serviced after 1400 operating hours of actual use. What's more is that the diesel particulate filter is replaced after 4200 hours by a remanufactured replacement filter. Altogether downtimes are also minimised.

Residual-value guarantee.

The Unimog is a fully dependable investment. A vehicle like the Unimog, which stands out with its great functionality, quality and reliability, is an especially sound investment. Models from the entire range of the model series achieve very good prices on the used-vehicle market. And deservedly so: a Unimog is designed for a long, hard-working life.

First-class life cycle costs.

- Use as a year-round workhorse for a wide variety of applications

- Lower consumption of fuel and AdBlue

- Efficient and large-series-proven Mercedes-Benz drive technology

- Low maintenance costs thanks to long maintenance intervals

- User-friendly cooling system

- Powerful premium engine brake reduces mechanical brake wear

- Very good corrosion protection

- Investment security thanks to very high residual value

- Attractive financing and leasing products

- Attractive services

The U 200 series.

U 219

Expert implement-carrying system for service providers and local authorities.

The U 219 is the smallest Unimog model with an extremely short wheelbase of just 2.8 mm. This makes it able to work in all those places where every millimetre counts. With its 140 kW (190 hp) engine, the U 219 model has enough power for almost any challenge that comes its way. Plus, it offers three different load values ranging from 7.5 to 10 t and so is well-equipped for a whole host of tasks.

The U 300 series.

U 319 | U 323 | U 327

High endurance for small and medium-sized towns.

With an engine output of 130 kW (177 hp) and a gross weight of 11 t, the U 319 reliably meets all the important municipal requirements. Together with the special models U 323 (170 kW/231 hp) and U 327 (200 kW/272 hp) with a permissible gross weight of up to 14 t, this model series fits the bill for everything for which an entire fleet would otherwise often be required.

The U 400 series.

U 423 | U 427 | U 430 | U 435

Versatile top performers.

If you're a Unimog user who moves heavy loads works on a wide range of jobs, the U 423 – U 435 models with gross vehicle weights from 11.99 t to 14.0 t are perfect for you! All four are available with either a short or a long wheelbase. The main differences are in their engine performance. This can be 170, 200, 220 or 260 kW (231, 272, 299 or 354 hp).

The U 500 series.

U 527 | U 530 | U 535

There's no obstacle it can't overcome.

Giving everything you need all year round yet still having power reserves to hand – this is what the 500 models with 200, 220 or 260 kW output (272, 299 or 354 hp) are all about. And with their gross vehicle weight of maximum 16.5 t, they can both shoulder heavy loads too. The wheelbases are 3.35 or 3.9 m (long version), the longest in the range.

Service & parts

Become

part of a legend!

We care about customer satisfaction. The Unimog is not just any old vehicle, it's an indestructible power pack, a versatile endurance runner and an adventurous all-rounder. In order to keep it at its best for many years to come, all professional Unimog users are provided with the very best support right from the start.

The Unimog is an automotive legend, in which every individual part has a role to play. Every service is decisive in how the story continues. That’s why every Mercedes-Benz Unimog service partner is more than just a workshop – it’s part of a legend. We are all part of this committed community, in which every part down to the smallest screw as well as every service appointment is crucial in making sure that the Unimog is cost effective and ready for action – empowering your Unimog to master everyday life with gusto – day in, day out.

Schweinfurt's Waterways and Shipping Authority in Schweinfurt has been very impressed with the Unimog's genuine parts.

As Norbert Eusemann chats with us about his Unimog, his excitement is contagious. The U 400 is the fourth model that the 57 year-old has been driving since he started working at the Volkach site of Schweinfurt's Waterways and Shipping Authority (WSA) in 1981. His passion for the Unimog was ignited when he was just eight years old and later, his passion became his profession. He is also very impressed with the service it provides. He says: "Mercedes-Benz Service has definitely earned its star."