The reinforcements to the cab underbody and the new tubular frame make the Unimog cab compliant with the ECE-R29/3 standard for cab stability.

Up for any challenge, tough off-road.

In recent years we have witnessed devastating forest fires like those in Southern Europe, record floods along the Danube and Elbe in Central Europe, violent hurricanes and autumnal storms throughout Europe, and disasters such as hailstorms and earthquakes. Proof, if you needed it, that the number of natural disasters is on the increase all around the world – and with them the need for major and special operations of fire services and disaster control organisations. All of this means that the key tasks of rescue, fire-fighting, recovery and protection are proving ever more challenging for emergency teams – and for the emergency vehicles they use. Which is why vehicles which are robust, reliable and above all capable of working off-road, like the Unimog, are an absolute necessity in our times.

Applications

Water tender vehicle.

Unimog alleviates critical situations on almost any terrain.

The Unimog is extremely popular with professional and voluntary fire services as a water tender vehicle and fire-fighting crew vehicle. Whether in urban areas, narrow old town streets, or out in the countryside and forested areas, the special truck combines off-road capability with special body compatibility and thus helps to bring important equipment to remote locations.

Rescue services around the globe put their trust in the Unimog.

Hubert Clavé, fire service lieutenant, Landes, France, explains: "We have been impressed by the Unimog's excellent ground clearance due to its drop centre axles, and by the vehicles' long service life and rugged design." Few know better than Clavé, as Landes is regularly hit by forest fires. These account for up to 500 call-outs for the fire service every year.

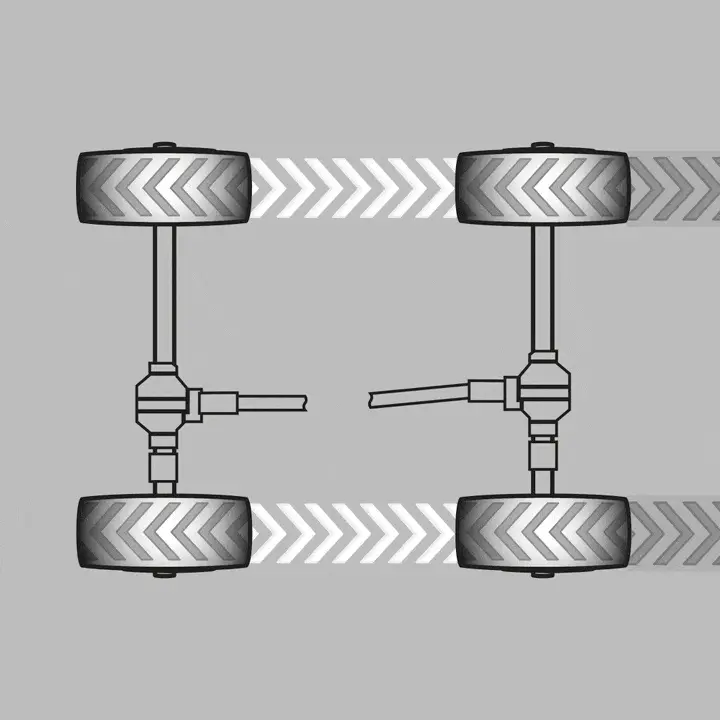

All-wheel steering.

The optional all-wheel steering available for the U 423 - U 535 models increases the manoeuvrability typical of the Unimog: it reduces the turning circle by around 20%, keeping the vehicle easy to manoeuvre in virtually every situation and almost completely eliminating the need for backing up around tight bends.

Unparalleled operational experience.

Continuing the tradition of getting help to wherever it's needed: the Mercedes-Benz Unimog owes its decades of success largely to its legendary chassis design. Since the 1950s, the Unimog concept has been synonymous with the finest engineering skills, delivering maximum robustness and traction in off-road conditions. Already in use as a fire service vehicle in the 50s: the Unimog U 25.

Applications

Equipment/tool vehicle

Unimog offers technical assistance wherever it is needed.

Rescue and recovery are among the Unimog's key assignments. Whether with the fire service, technical relief agencies or other organisations – the two series are pre-equipped as basic vehicles for a wide range of applications. And with a driving speed of up to 89 km/h on paved roads, they get to where they are needed quickly. If more manpower is needed, the extreme off-road Unimog with optional crew cab can bring the entire team along.

"The Unimog U 5023 represents a whole new dimension when compared to its predecessor. The increase in load capacity from around two to roughly four tonnes makes us twice as effective in itself, because we can bring double the amount of equipment to the incident in a single trip."

Joachim Bauer, local representative of the technical relief agency, Laaber, Germany

Applications

Crane truck.

With a rear-mounted crane, the Unimog plays a key role in disaster relief operations.

Rescue workers at the technical relief agency rely on vehicles with extreme off-road capabilities. With the Unimog U 5023, for example, they can protect a region of Bavaria that is at particular risk by flooding.

A race against time to clear the snow.

In the chaos of an Austrian winter, the extreme off-road Unimog clears snow from the roofs of buildings. It is a race against time for the firefighters, technical relief agency and other emergency personnel endeavouring to remove the snow before buildings collapse.

Applications

Ambulance.

The Unimog with box body has comprehensive medical equipment on board.

There are always people in need of assistance. In order to cope with such unforeseen situations, it is essential that rescue services and disaster responce teams have the right technical support. In chaotic disaster areas, relief organisations with their rescue vehicles are usually in high demand. But most rescue vehicles with chassis for normal roads reach their limits where the Unimog really comes into its own as an ambulance.

Applications

Maritime rescue.

As a reliable multi-purpose vehicle, the Unimog impresses with a large fording depth of up to 1.2 m.

Sea, deep sand, high dunes and rocky coastlines: equipped for search-and-rescue missions with a thermal imaging camera and radar positioning, as well as ambulance equipment and a lifeboat, the Unimog is used in various locations by coast guards, lifesavers and others.

Ready to help quickly.

To move the Unimog from the road onto the track, a straight track run of five metres is sufficient – this allows the Unimog to be set on the track almost anywhere. The implement carrier also scores highly thanks to its short changeover time – it only takes three minutes to switch from road mode to rail mode.

Unique dual operation.

The new Unimog for lightning-fast service and rescue operations in Magdeburg. “We ordered the Unimog because we needed a vehicle that could get to the site extremely quickly in critical situations – such as a tram accident – and then get on the track in just a few minutes,” explains the project manager, describing the requirements.

Product benefits

The extreme off-road Unimog.

Off road perfection.

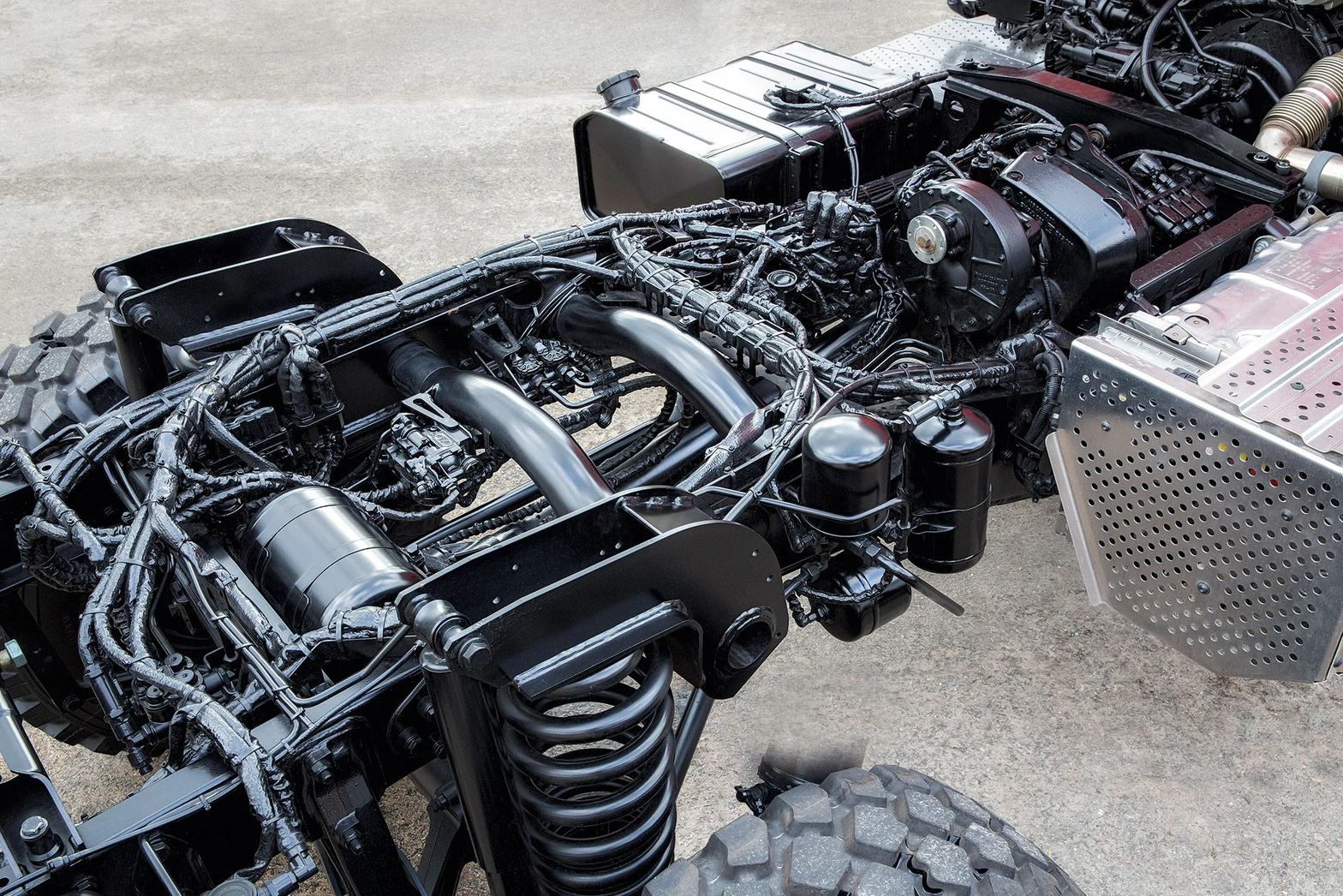

You need to be tough to guarantee maximum performance in the harshest of conditions. The Unimog is equal to the challenge thanks to its offset welded frame, thrust tube technology for extreme diagonal torsional flexibility up to 600 mm, excellent angle of approach/departure, drop centre axles giving a high ground clearance, all-wheel drive and differential locks, not to mention high traction and excellent gradeability.

- High durability, safety and reliability when used in woodland and off-road

- Welded frame, solid construction, steel bumper with protected headlamps, cable set positioned above the frame, all-steel cab

- Torsionally flexible mounting of cab, powertrain and attachments

- Torque tube design to protect the powertrain

- Large angle of approach/departure and ramp breakover angle

- Drop centre axles for high ground clearance and assemblies (tank, battery housing etc.) in protected position

- Coil springs with compact design and long spring travel

- Gearbox with special off-road reduction gear

- Single tyres for high traction

- Automatic tyre pressure control system

- Tirecontrol plus ex works

- Parametrisable special module and standardised construction interfaces ex works

- Floor assembly with torsionally flexible mounting or body mount

- Hydraulics for cable winch operation (60 l /min) ex works

- Bracket for self-recovery cable winch integrated in front attachment

- Front implement mounting plate for snow plough, earth mover or front sweeper for use in disaster response

- Engine power take-off with 600 Nm or transmission-driven power take-off with rapid transmission ratio, e.g. for operating firefighting pumps

- Round roof hatch and folding seat for safely fighting forest fires direct from cab

- Compact design, suitable for low entrances and older fire stations

- "Pump & roll" tactic possible thanks to engine-driven or transmission-driven power take-off and off-road gear range for driving at low speed

- Good visibility and ride comfort thanks to cab-behind-engine truck design with seat position behind the front axle

- Fording capability to depths of 0.8 m, optionally 1.2 m, for use in flood waters

- Front and reversing camera

- High durability, safety and reliability when used in woodland and off-road

- Welded frame, solid construction, steel bumper with protected headlamps, cable set positioned above the frame, all-steel cab

- Torsionally flexible mounting of cab, powertrain and attachments

- Torque tube design to protect the powertrain

- Large angle of approach/departure and ramp breakover angle

- Drop centre axles for high ground clearance and assemblies (tank, battery housing etc.) in protected position

- Coil springs with compact design and long spring travel

- Gearbox with special off-road reduction gear

- Single tyres for high traction

- Automatic tyre pressure control system

- Tirecontrol plus ex works

- High permissible axle loads with lightweight chassis construction allow sizeable payloads

- High transport capacity for extinguishers and loading

- Parametrisable special module and standardised construction interfaces ex works

- Floor assembly with torsionally flexible mounting or body mount

- Hydraulics for cable winch operation (60 l /min) ex works

- Bracket for self-recovery cable winch integrated in front attachment

- Front implement mounting plate for snow plough, earth mover or front sweeper for use in disaster response

- Engine power take-off with 600 Nm or transmission-driven power take-off with rapid transmission ratio, e.g. for operating firefighting pumps

- Round roof hatch and folding seat for safely fighting forest fires direct from cab

- Compact design, suitable for low entrances and older fire stations

- "Pump & roll" tactic possible thanks to engine-driven or transmission-driven power take-off and off-road gear range for driving at low speed

- Good visibility and ride comfort thanks to cab-behind-engine truck design with seat position behind the front axle

- Fording capability to depths of 0.8 m, optionally 1.2 m, for use in flood waters

- Front and reversing camera

Extreme off-road capability.

The extreme off-road Unimog is a true off-road professional. It owes its high ground clearance to drop centre axles that allow obstacles to be overcome with ease. The hub reduction gear is protected against dust and dirt. The Unimog’s extreme torsional capability is based on its torsional frame: All wheels are in constant contact with the ground. The chassis enables a large axle articulation of max. 30° through the use of torque tube technology and coil springs, as well as a minimum stress load on the body due to double three-point mounting. The cab and body can be twisted by up to 12° relative to each other. Uncompromising all-wheel drive, differential locks and constant maximum traction also ensure extreme off-road capability.

Tire Control plus.

The switching logic allows the user to choose between the pre-set "Road", "Sand" and "Rough" modes. This means the correct mode for the current road surface can be set intuitively, making operator error virtually impossible. TireControl also brings benefits for nature: driving off-road with lowered tyre pressure improves traction while reducing the impact on the surface.

Capable of fording to a depth of 1.2 m.

The drive system of the extreme off-road Unimog is designed to enable the vehicle to ford to depths of up to 0.8 m or, on request, 1.2 m. In addition, the Unimog is also equipped with waterproof main headlights, central high ventilation system and a double seal on the wheel hub. The catalytic converter and upright exhaust ultimately make the vehicle fully suitable for fording.

Use of implements.

An advantage when used with front-mounted implements is the front mounting plate for attachment of a snowplough, earth pusher or front-mounted sweeper for use in disaster operations. In addition, the Unimog scores highly ex works with hydraulics for cable winch operation (60 l/min). The cable winch holder for a self-recovery winch is integrated into the front attachment. A gearbox PTO is specially available for operation of a fire extinguisher pump.

Cab.

With a single cab for work crews (1 + 2), the Unimog has two fullyfledged individual seats and a centre seat. Alternatively, the crew cab can provide space for up to 7 people (1 + 6) ex works, a high cab roof for more headroom and four wide-opening doors as well as generous storage space under the fold-down rear seat bench. A roof hatch and a folding seat are optionally available for use during extinguishing operations.

Heat protection.

The fireproof steel cab with ECE-R29 certification protects emergency crews. In addition, a heat protection package is also available ex works. This includes a special covering for all important cables, in order to protect them from extreme heat or other damage. In addition, all of the Unimog's major assemblies and technical components are mechanically protected.

Product benefits

The Unimog implement carrier.

All-rounder for fire service deployment.

The Unimog implement carrier supports emergency services as a versatile work machine with flexible attachment and mounting options wherever help is needed. It is not only impressive when it comes to fire extinguishing and disaster protection – the special truck is also popular among fire services and local authorities for winter service operations. This makes its operation particularly economical.

- High-torque engines with 140 to 260 kW (190 to 354 hp) and 750 to 1,380 Nm torque

- High-performance gearbox with practically-oriented graduation

- Driving speed of up to 100 km/h on paved roads

- Dual circuit load-sensing hydraulics for driving and controlling attachments/implements

- Mechanical front PTO shaft delivering up to 160 kW, e.g. for mud and water pumps

- Compact dimensions: from a width of 2.2 m for manoeuvring in confined spaces

- Short wheelbases: 2,800 mm to 3,900 mm

- Small turning circle (from 12.6 m) for outstanding manoeuvrability and agility

- All-wheel steering for models U 423 to U 535

- High-torque engines with 140 to 260 kW (190 to 354 hp) and 750 to 1,380 Nm torque

- High-performance gearbox with practically-oriented graduation

- Driving speed of up to 100 km/h on paved roads

- Dual circuit load-sensing hydraulics for driving and controlling attachments/implements

- Mechanical front PTO shaft delivering up to 160 kW, e.g. for mud and water pumps

- Generous panoramic cab

- Camera monitoring system with up to three cameras to improve close-range field of vision

- High payload (10 t – 16.5 t permitted gross vehicle weight)

- Collaborations with various attachment and implement manufacturers for wide range of applications

- Modern and ergonomic interior

- Operating logic conforms to volume series Mercedes-Benz Trucks

- Multi-function steering wheel

- Central tyre pressure control system Tirecontrol plus

Single tyres.

The principle: The rear wheels follow in the tracks made by the front wheels. This improves traction and spares the terrain.

Tire Control plus.

The switching logic allows the user to choose between the pre-set "Road", "Sand" and "Rough" modes. This means the correct mode for the current road surface can be set intuitively, making operator error virtually impossible. TireControl also brings benefits for nature: driving off-road with lowered tyre pressure improves traction while reducing the impact on the surface.

Performance.

The implement carrier is both powerful and economical. Its high-torque engines and high-performance transmission with practical gradations have proven to be especially practical, as have the driving speed of up to 100 km/h on paved roads and the low-maintenance and low-wear pneumatic brake system.

Safety.

As a state-of-the-art commercial vehicle, the Unimog makes no compromises when it comes to safety. With its active and passive safety systems, Unimog users and other road users alike are kept well protected. The panoramic cab ensures optimum visibility in deployment on and off the road. The optionally available camera monitoring system with up to three cameras also helps to improve visibility at close range.

Product benefits

Compliance with firefighting standards.

Rescue, extinguishing, recovery, protection according to standard.

The European firefighting standard EN 1846 can be met with the Mercedes-Benz Unimog. It specifies the general technical features and equipment required for fire service vehicles. The national versions are based on this standard and describe country-specific vehicle categories.

European standard.

The EN 1846 standard classifies vehicles into three mass classes and three applicability categories.

Mass classes (permissible gross weight): Light (L): 3 to 7.5 t, Medium (M): 7.5 to 16 t, Super (S): greater than 16 t. Usability categories: 1 for on-road use, 2 for rough-road use, 3 for off-road use.

Thanks to its characteristics, the Unimog fulfils the highest demands, equal to those of the M2/M3 categories.

| U 5023 | M3 | U 219 | M2 | |

| Angle of approach front/rear | 46°/50° | mins. 35° | 25°/37° | mins. 23° |

| Ramp angle | 34° | mins. 30° | 27° | mins. 18° |

| Ground clearance | 420 mm | mins. 300 mm | 335 mm | mins. 230 mm |

| Category | Standard¹ | Unimog type | Engine power² | perm. gross weight | perm. gross weight according to standard | Main task | Crew | (Minimum) tank capacity |

|---|---|---|---|---|---|---|---|---|

| TLF 2000 water tending vehicle | DIN 14530–18 | U 219 | 140 kW (190 hp) | 10.5 t | 14 t | Firefighting | 1 + 2 | 2,000 l |

| TLF 2000 water tending vehicle | DIN 14530–18 | U 5023 | 170 kW (231 hp) | 14.5 t | 14 t | Firefighting | 1 + 2 , 2 + 2, or 1 + 5 | 2,000 l |

| TLF 3000 water tender vehicle | DIN 14530–22 | U 323/U 423 | 170 kW (231 hp) | 12.5 – 14.5 t | 14 t | Firefighting | 1 + 2 | 3,000 l |

| TLF 3000 water tender vehicle | DIN 14530–22 | U 327/U 427 | 200 kW (272 hp) | 14 t | 14 t | Firefighting | 1 + 2 | 3,000 l |

| TLF 3000 water tender vehicle | DIN 14530–22 | U 430 | 220 kW (299 hp) | 14 t | 14 t | Firefighting | 1 + 2 | 3,000 l |

| TLF 3000 water tender vehicle | DIN 14530–22 | U 435 | 260 kW (354 hp) | 14 t | 14 t | Firefighting | 1 + 2 | 3,000 l |

| TLF 3000 water tender vehicle | DIN 14530–22 | U 5023 | 170 kW (231 hp) | 14.5 – 15 t³ | 14 t | Firefighting | 1 + 2 , 2 + 2, or 1 + 5 | 3,000 |

| TLF 4000 water tender vehicle | DIN 14530–21 | U 5023 | 170 kW (231 hp) | 14.5 t | 18 t | Firefighting | 1 + 2 | ≥ 4000 l + foam |

| TLF 4000 water tender vehicle | DIN 14530–21 | U 530 | 220 kW (299 hp) | 16.5 t | 18 t | Firefighting | 1 + 2 | ≥ 4000 l + foam |

| TLF 4000 water tender vehicle | DIN 14530–21 | U 535 | 260 kW (354 hp) | 16.5 t | 18 t | Firefighting | 1 + 2 | ≥ 4,000 l + foam |

| Rescue vehicle RW | DIN 14555–3 | U 5023 | 170 kW (231 hp) | 14.5 t | 16 t | Technical Assistance | 1 + 2 | – |

| Rescue vehicle RW | DIN 14555–3 | U 530 | 220 kW (299 hp) | 16.5 t | 16 t | Technical Assistance | 1 + 2 | – |

| Rescue vehicle RW | DIN 14555–3 | U 535 | 260 kW (354 hp) | 16.5 t | 16 t | Technical Assistance | 1 + 2 | – |

¹ The DIN standards stated here refer to Germany. Other country-specific firefighting standards apply elsewhere.

² Euro V variants are also available on request, depending on approval capability.

³ If a vehicle’s centre of gravity is maintained, incl. body at max. 1,450 mm.

For detailed information or questions, please contact the authorised Unimog sales partner in your market.

The U 200 series.

U 219

Expert implement-carrying system for service providers and local authorities.

The U 219 is the smallest Unimog model with an extremely short wheelbase of just 2.8 mm. This makes it able to work in all those places where every millimetre counts. With its 140 kW (190 hp) engine, the U 219 model has enough power for almost any challenge that comes its way. Plus, it offers three different load values ranging from 7.5 to 10 t and so is well-equipped for a whole host of tasks.

The U 300 series.

U 319 | U 323 | U 327

High endurance for small and medium-sized towns.

With an engine output of 130 kW (177 hp) and a gross weight of 11 t, the U 319 reliably meets all the important municipal requirements. Together with the special models U 323 (170 kW/231 hp) and U 327 (200 kW/272 hp) with a permissible gross weight of up to 14 t, this model series fits the bill for everything for which an entire fleet would otherwise often be required.

The U 400 series.

U 423 | U 427 | U 430 | U 435

Versatile top performers.

If you're a Unimog user who moves heavy loads works on a wide range of jobs, the U 423 – U 435 models with gross vehicle weights from 11.99 t to 14.0 t are perfect for you! All four are available with either a short or a long wheelbase. The main differences are in their engine performance. This can be 170, 200, 220 or 260 kW (231, 272, 299 or 354 hp).

The U 500 series.

U 527 | U 530 | U 535

There's no obstacle it can't overcome.

Giving everything you need all year round yet still having power reserves to hand – this is what the 500 models with 200, 220 or 260 kW output (272, 299 or 354 hp) are all about. And with their gross vehicle weight of maximum 16.5 t, they can both shoulder heavy loads too. The wheelbases are 3.35 or 3.9 m (long version), the longest in the range.

The U 5023.

Universal extreme athlete.

The U 5023 is the right choice for anyone who needs maximum off-road performance. 3.8 m wheelbase, a fording depth of up to 1.2 m, a permissible gross vehicle weight of 15.0 t and an impressive angle of approach/departure of 44°/50° make the Unimog a reliable workhorse.

Service & parts

Become

part of a legend!

We care about customer satisfaction. The Unimog is not just any old vehicle, it's an indestructible power pack, a versatile endurance runner and an adventurous all-rounder. In order to keep it at its best for many years to come, all professional Unimog users are provided with the very best support right from the start.

The Unimog is an automotive legend, in which every individual part has a role to play. Every service is decisive in how the story continues. That’s why every Mercedes-Benz Unimog service partner is more than just a workshop – it’s part of a legend. We are all part of this committed community, in which every part down to the smallest screw as well as every service appointment is crucial in making sure that the Unimog is cost effective and ready for action – empowering your Unimog to master everyday life with gusto – day in, day out.

Schweinfurt's Waterways and Shipping Authority in Schweinfurt has been very impressed with the Unimog's genuine parts.

As Norbert Eusemann chats with us about his Unimog, his excitement is contagious. The U 400 is the fourth model that the 57 year-old has been driving since he started working at the Volkach site of Schweinfurt's Waterways and Shipping Authority (WSA) in 1981. His passion for the Unimog was ignited when he was just eight years old and later, his passion became his profession. He is also very impressed with the service it provides. He says: "Mercedes-Benz Service has definitely earned its star."