Unimog with Verdegro's impact damping system safes roadworks.

Motorways are actually safe. Nevertheless, rear-end collisions with sometimes serious consequences occur every now and again, particularly in roadworks. In many cases, workers are at risk during mowing operations or in roadworks: careless drivers overlook bottlenecks or barriers and collide with security vehicles almost unbraked. The new impact damping system from the Dutch company Verdegro could help – at least when it comes to serious injuries to the drivers in the safety vehicles and damage to the material itself.

Less damage thanks to absorbed impact energy.

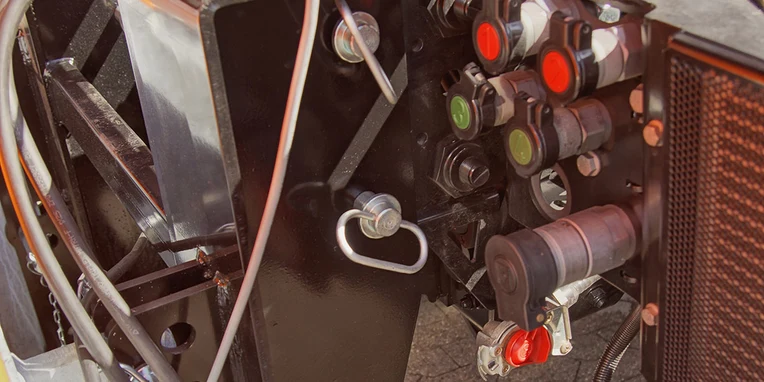

Following approval by Mercedes-Benz Special Trucks in Wörth, the impact damping system TMA-US on a Unimog can ensure greater safety at construction sites. To achieve this, the driver simply folds out the damping protection connected to a signalling system at the rear of the vehicle. The honeycomb structure of the damping elements made of light metal and galvanized steel absorbs a large part of the impact energy in rear-end collisions – and greatly enhances the existing damping properties of the Unimog platform. This means that in the event of a collision, both the vehicle of the person causing the accident and the working vehicle itself are considerably less affected: more safety for all road users.

Unimog safety advantages at a glance.

This can save lives and keeps accident damage to a minimum. The Verdegro impact damping system has been tested according to the NCHRP 350 crash test at a speed of 100 km/h and, following testing by Mercedes-Benz Special Trucks, it is approved for installation on the Unimog. Unimog partner Merex is responsible for distribution in Germany.