High mobility for high voltage.

No matter if you're wanting to tap into new energy sources, if opencast mining is your vocation, or if you're in charge of the maintenance, checking and repairing of worldwide supply networks – thanks to its unique vehicle concept, the Unimog takes you to wherever you need to be: fully loaded and with full power. And when you work in the energy industry, this means taking a trip off the beaten track...every single day.

Applications

Line construction and maintenance.

With its equally impressive driving characteristics, off-road capability and work features, the Unimog is made to measure for the demands of the energy industry.

A late-night storm, a flash of lightning, and suddenly the stability of the power grid is at risk. It's time for urgent action. The Unimog stands ready. It can perform even on rough terrain. Depending on the vehicle and body configuration, both Unimog model series have been tried and tested in the fields of power cable and pipeline installation, as well as maintenance work: At any time of year, whatever the weather, day or night.

Reduced installation time.

Cable winch attachment points and special attachment fittings for heavy equipment and crane bodies ex works are particularly important in the energy industry. These help to reduce assembly times and securely connect bodies to the vehicle, for example when using insulated work platforms for work at heights of up to 27 m.

High levels of driving comfort and high traction.

The Unimog also puts on an impressive off-road performance thanks to features like all-wheel drive, single tyres that protect the ground and the tyre pressure control system TireControl plus. What's more, there is a wide range of tyre treads to suit every surface.

Device drive and interfaces.

Powerful mechanical, electric and hydraulic implement drives as well as standardised interfaces and attachment points enable easy integration of a wide range of bodies suitable for use in the energy industry – e.g. cable winches, cranes up to 27 m, insulated elevating work platforms including supports, and many more besides.

Applications

Opencast mining.

The Unimog masters even the most difficult terrain.

In this case, it's the vast scale of the sites, which is characteristic of opencast mining. This makes it all the more important to have vehicles that can get people and materials to the site quickly. Whether in use as a crew transporter, fuel tanker, mobile workshop or with a mounted crane: with its excellent off-road capabilities, the Unimog is particularly at home in opencast mines. And no wonder, with its superior off-road characteristics: significant ground clearance, fantastic angles of approach and departure and ramp angles, and the possibility of increasing traction at the push of a button with the TireControl plus tyre pressure control system.

Star Wars-like backdrop as the stage for an extreme test.

The Hambach opencast mine has long been regarded as the ideal test site – and so it was a matter of course that the 126 Unimogs in total that belong to the fleet would be put through their paces here too. “Most of our Unimogs are equipped with a platform body, crane and cable winch, which are the tools we need most here”, explains Jörg Rübsteck.

Product benefits

The Unimog implement carrier.

A true all-rounder: whatever the weather.

The Unimog implement carrier supports emergency services as a versatile work machine with flexible attachment and mounting options. It's particularly economical thanks to its many application possibilities, all of which can be used 365 days a year – for example in winter service for contractors.

Off-road capability.

The Unimog: truly impressive, both on and off the road. Its robust chassis concept with differential locks and drop centre axles as well as permanent all-wheel drive and all-wheel steering (from Unimog U 423) make the Unimog a powerful vehicle even in remote locations. Its very short wheelbase from 2,800 mm keeps it manoeuvrable in virtually any situation.

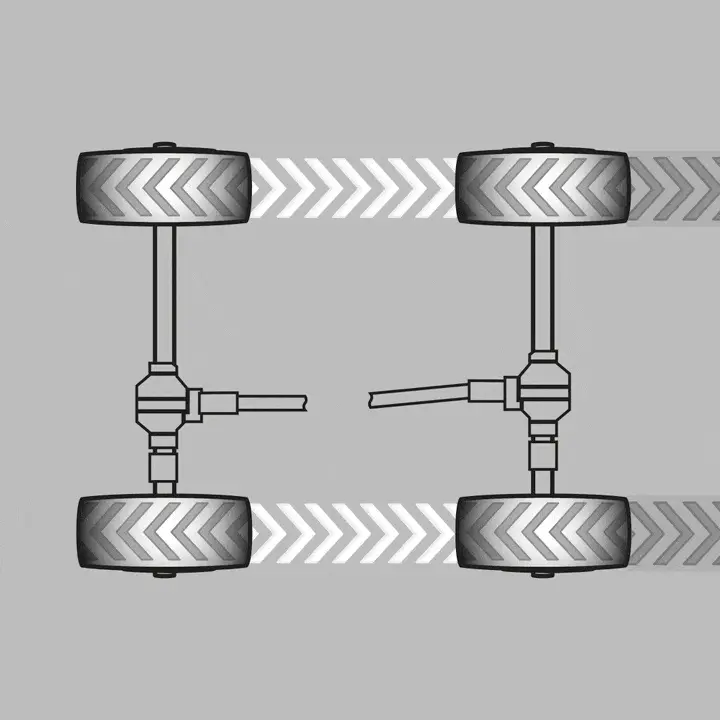

Single tyres.

The principle: The rear wheels follow in the tracks made by the front wheels. This improves traction and spares the terrain.

Tire-Control plus.

The switching logic allows the user to choose between the pre-set "Road", "Sand" and "Rough" modes. This means the correct mode for the current road surface can be set intuitively, making operator error virtually impossible. TireControl also brings benefits for nature: driving off-road with lowered tyre pressure improves traction while reducing the impact on the surface.

Product benefits

The extreme off-road Unimog.

Outstanding off-road capability is the trademark of the off-road Unimog series.

Thanks to its cranked and welded vehicle frames, torque tube technology for extreme diagonal torsional flexibility of up to 600 mm, wide angles of approach and departure and ramp breakover angle, portal axles providing ample ground clearance, all-wheel drive and differential locks, and high traction and climbing ability, this off-road pro can take on the toughest of challenges.

Extreme off-road capability.

The extreme off-road Unimog is a true off-road professional. It owes its high ground clearance to drop centre axles that allow obstacles to be overcome with ease. The hub reduction gear is protected against dust and dirt. The Unimog’s extreme torsional capability is based on its torsional frame: All wheels are in constant contact with the ground. The chassis enables a large axle articulation of max. 30° through the use of torque tube technology and coil springs, as well as a minimum stress load on the body due to double three-point mounting. The cab and body can be twisted by up to 12° relative to each other. Uncompromising all-wheel drive, differential locks and constant maximum traction also ensure extreme off-road capability.

Impressive data.

| Output | 170 kW (231 hp) |

| Drive | Engaging all-wheel drive |

| Wheelbase | 3,850 mm |

| GVW | 10.3-14.5 t |

| Turning circle | 16.3 m |

| Speed | 89 km/h* |

* Governed legal speed limit.

Transmissions.

The transmission of the Unimog is the basis for its reputation as a legendary off-road professional vehicle. Optionally, it can be extended by an off-road gear range with 8 additional forward and reverse gears. As well as the rear-axle drive with pneumatically engageable all-wheel drive, the standard equipment also includes the electro-pneumatic gearshift (EPS).

Fording capability up to 0.8 m – optional up to 1.2 m.

The drive system of the extreme off-road Unimog is designed to enable the vehicle to ford to depths of up to 0.8 m or, on request, 1.2 m. In addition, the Unimog is also equipped with waterproof main headlights, central high ventilation system and a double seal on the wheel hub. The catalytic converter and upright exhaust ultimately make the vehicle fully suitable for fording.

Robustness.

Thanks to the protected powertrain as standard with torque tube technology and encapsulations, the Unimog with off-road capabilities is guaranteed to impress with its extraordinary robustness ex works. This off-road pro can master the most difficult of terrain with absolute reliability – with operating times spanning more than 25 years in many cases.

Use of implements.

The Unimog offers attachment and mounting interfaces as well as powerful machine drives ex works. For example, a crane or aerial work platform can be set up as easily as a toolbox. The Unimog also impresses with its hydraulic power, which can supply a self-recovery winch with up to 60 l/min, for example.

The U 200 series.

U 219

Expert implement-carrying system for service providers and local authorities.

The U 219 is the smallest Unimog model with an extremely short wheelbase of just 2.8 mm. This makes it able to work in all those places where every millimetre counts. With its 140 kW (190 hp) engine, the U 219 model has enough power for almost any challenge that comes its way. Plus, it offers three different load values ranging from 7.5 to 10 t and so is well-equipped for a whole host of tasks.

The U 300 series.

U 319 | U 323 | U 327

High endurance for small and medium-sized towns.

With an engine output of 130 kW (177 hp) and a gross weight of 11 t, the U 319 reliably meets all the important municipal requirements. Together with the special models U 323 (170 kW/231 hp) and U 327 (200 kW/272 hp) with a permissible gross weight of up to 14 t, this model series fits the bill for everything for which an entire fleet would otherwise often be required.

The U 400 series.

U 423 | U 427 | U 430 | U 435

Versatile top performers.

If you're a Unimog user who moves heavy loads works on a wide range of jobs, the U 423 – U 435 models with gross vehicle weights from 11.99 t to 14.0 t are perfect for you! All four are available with either a short or a long wheelbase. The main differences are in their engine performance. This can be 170, 200, 220 or 260 kW (231, 272, 299 or 354 hp).

The U 500 series.

U 527 | U 530 | U 535

There's no obstacle it can't overcome.

Giving everything you need all year round yet still having power reserves to hand – this is what the 500 models with 200, 220 or 260 kW output (272, 299 or 354 hp) are all about. And with their gross vehicle weight of maximum 16.5 t, they can both shoulder heavy loads too. The wheelbases are 3.35 or 3.9 m (long version), the longest in the range.

The U 5023.

Universal extreme athlete.

The U 5023 is the right choice for anyone who needs maximum off-road performance. 3.8 m wheelbase, a fording depth of up to 1.2 m, a permissible gross vehicle weight of 15.0 t and an impressive angle of approach/departure of 44°/50° make the Unimog a reliable workhorse.

Service & parts

Become

part of a legend!

We care about customer satisfaction. The Unimog is not just any old vehicle, it's an indestructible power pack, a versatile endurance runner and an adventurous all-rounder. In order to keep it at its best for many years to come, all professional Unimog users are provided with the very best support right from the start.

The Unimog is an automotive legend, in which every individual part has a role to play. Every service is decisive in how the story continues. That’s why every Mercedes-Benz Unimog service partner is more than just a workshop – it’s part of a legend. We are all part of this committed community, in which every part down to the smallest screw as well as every service appointment is crucial in making sure that the Unimog is cost effective and ready for action – empowering your Unimog to master everyday life with gusto – day in, day out.

Schweinfurt's Waterways and Shipping Authority in Schweinfurt has been very impressed with the Unimog's genuine parts.

As Norbert Eusemann chats with us about his Unimog, his excitement is contagious. The U 400 is the fourth model that the 57 year-old has been driving since he started working at the Volkach site of Schweinfurt's Waterways and Shipping Authority (WSA) in 1981. His passion for the Unimog was ignited when he was just eight years old and later, his passion became his profession. He is also very impressed with the service it provides. He says: "Mercedes-Benz Service has definitely earned its star."