You can rely on the extreme off-road Unimog – even for disaster relief.

Vehicle concept

You can reach milestones. Or set new ones.

Scree, snow, sand and unsurfaced roads: the extreme off-road Unimog will find a way.

All-wheel drive, fording capability and extreme torsional flexibility give the robust commercial vehicle a head start in rough terrain: the Unimog will take crews, material and heavy implements to any location, no matter how remote.

This gives the Unimog extreme off-road capabilities:

- Robust and compact vehicle design

- Torsionally flexible frame concept with up to 600 mm diagonal torsion

- Short frame overhangs for wide angles of approach and departure

- All-wheel drive for powerful traction

- Single tyres

- Great ground clearance thanks to portal axles

- Optional TireControl tyre pressure control system plus practical default settings

- Differential locks

- Fording capability to a depth of 1.20 m

- Off-road ratio for a climbing capability of up to 100%

The value-for-money Unimog has:

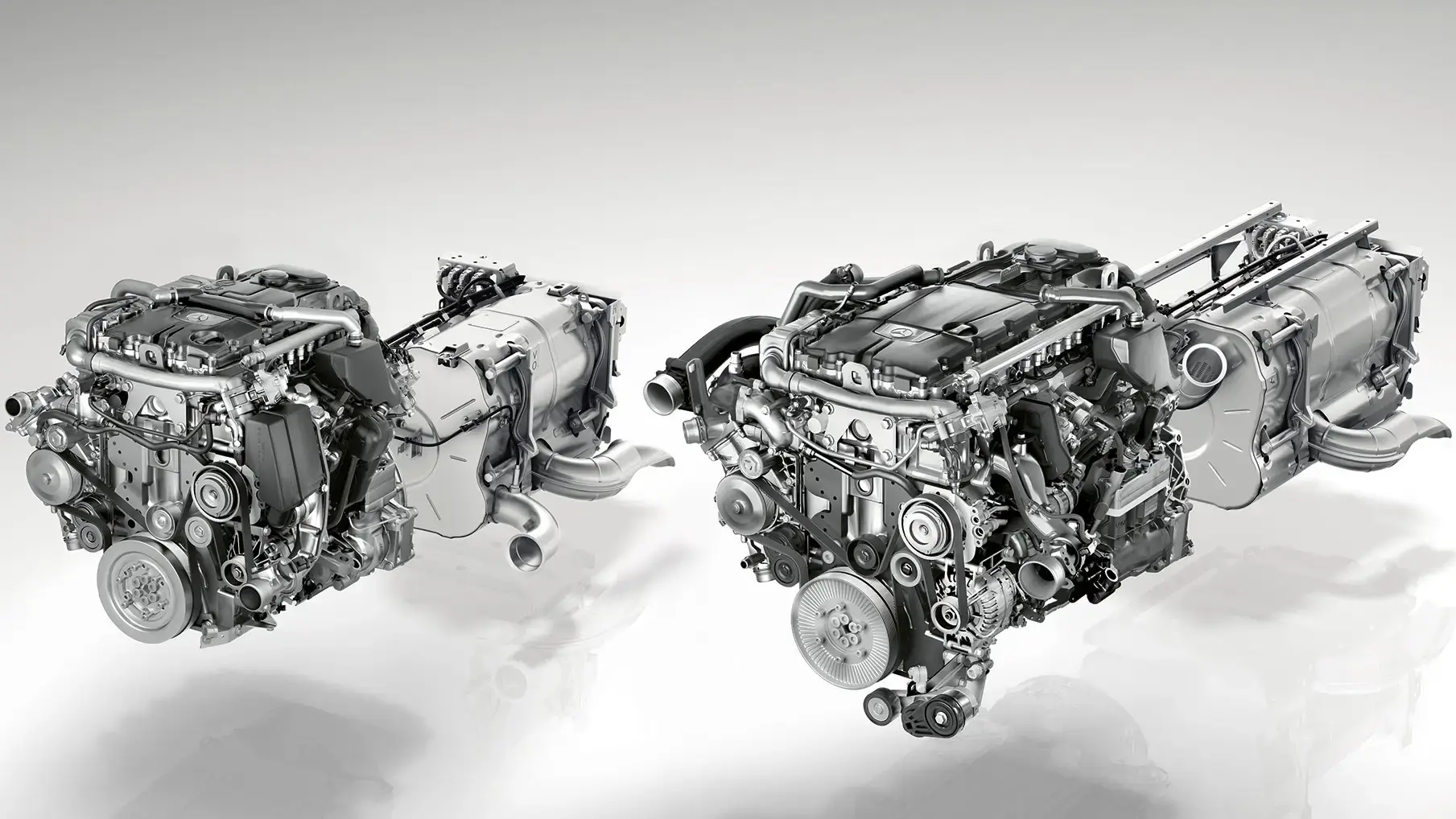

- Efficient drive technology from Mercedes-Benz that has proven its worth in series production

- Low consumption of fuel, AdBlue® and engine oil

- Long maintenance intervals (1,400 operation hours/35,000 km) for low maintenance costs

- Vehicle speed of up to 89 km/hr (locked)

- Powerful premium engine brake

- Versatile application potential for high capacity use

- High resale value

This makes the Unimog robust and reliable:

- Robust steel cab

- Durable thanks to high-quality workmanship

- Large radiator in aprotected location above the bumper

- Entirely welded frame and encapsulated drivetrain for an extended service life

- High reliability thanks to large-scale production and testing

- Proven operational readiness from -40 to +50 °C

The practical Unimog has:

- Transmission power take-offs still usable if sub-frame used for attachments

- Engine PTO as mechanical interfacefor implement drive (600 Nm)

- Standardised attachment points

- Powerful vehicle hydraulics

- Crew cab with space for up to seven persons available

- Clearly structured operating elements, all within easy reach

- Engine in centre position for balanced axle load distribution

This gives the Unimog extreme off-road capabilities:

- Robust and compact vehicle design

- Torsionally flexible frame concept with up to 600 mm diagonal torsion

- Short frame overhangs for wide angles of approach and departure

- All-wheel drive for powerful traction

- Single tyres

- Great ground clearance thanks to portal axles

- Optional TireControl tyre pressure control system plus practical default settings

- Differential locks

- Fording capability to a depth of 1.20 m

- Off-road ratio for a climbing capability of up to 100%

The value-for-money Unimog has:

- Efficient drive technology from Mercedes-Benz that has proven its worth in series production

- Low consumption of fuel, AdBlue® and engine oil

- Long maintenance intervals (1,400 operation hours/35,000 km) for low maintenance costs

- Vehicle speed of up to 89 km/hr (locked)

- Powerful premium engine brake

- Versatile application potential for high capacity use

- High resale value

The high performance Unimog has:

- Efficient engine with 170 kW (231 hp) and high torque

- Transmission with short shift times

- Large-capacity batteries

- High load ratings

- Powerful mechanical, hydraulic and electric drives for bodies and implements

This makes the Unimog robust and reliable:

- Robust steel cab

- Durable thanks to high-quality workmanship

- Large radiator in aprotected location above the bumper

- Entirely welded frame and encapsulated drivetrain for an extended service life

- High reliability thanks to large-scale production and testing

- Proven operational readiness from -40 to +50 °C

The user-friendly Unimog has:

- Short-nosed cab with compact dimensions

- Generous, ergonomic interior

- Innovative and straightforward operating concept

- Ergonomic seating position behind the axle

- High-performance heating and air-conditioning system

- Front camera to increase field of vision

- Reversing camera

The environmentally friendly Unimog has:

- Efficient BlueTec6 engine generation

- Complies with Euro VI emission standard

The practical Unimog has:

- Transmission power take-offs still usable if sub-frame used for attachments

- Engine PTO as mechanical interfacefor implement drive (600 Nm)

- Standardised attachment points

- Powerful vehicle hydraulics

- Crew cab with space for up to seven persons available

- Clearly structured operating elements, all within easy reach

- Engine in centre position for balanced axle load distribution

Chassis expertise: Knows virtually no limits. Not even the tree line.

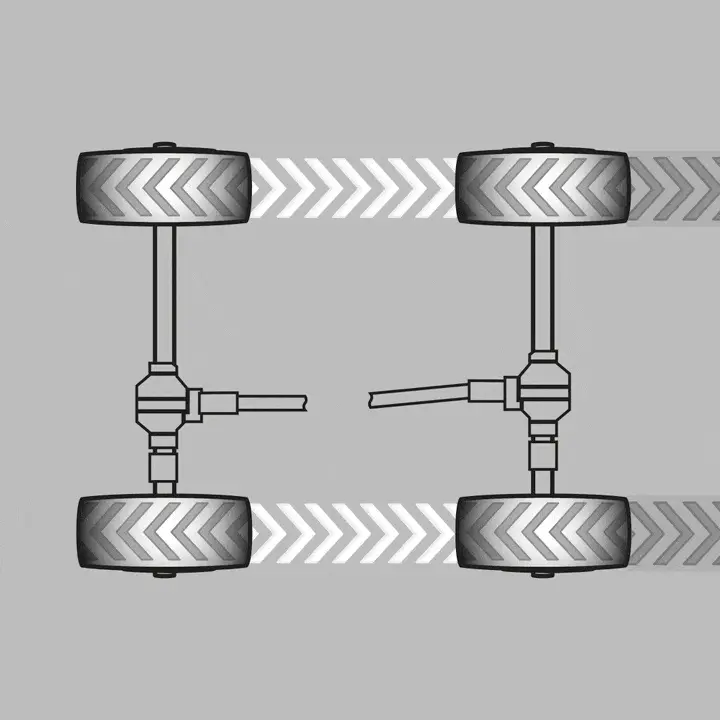

The unique off-road capability of the Unimog starts with its suspension system: The torsionally flexible frame with three-point mounting of the cab, engine and transmission system, as well as the suspension mounting with torque tube engineering, wishbone steering and coil springs, ensure articulation of up to 30°. All-wheel drive, single tyres, TireControl tyre pressure control system plus differential locks ensure maximum off-road traction. And the vehicle's low centre of gravity ensures stability even on extremely steep slopes. When off-road, the Unimog also benefits especially from its ground clearance of up to half a metre. This is made possible by its portal axles as well as by the positioning of all major assemblies above the lower edge of the frame.

System expertise: the Unimog is more than just a vehicle.

A true utility vehicle that is fully operational even in the most remote areas – the Unimog is the embodiment of off-road mobility. Even in the middle of the countryside, mechanical, hydraulic and electric drives deliver the right power for different implements and bodies. The well thought-out drive concept predestines the vehicle for a wide variety of tasks and applications. Three attachment spaces with standardised connection points make it easy to attach bodies and change implements. Mercedes-Benz has been cooperating with international equipment and body manufacturers for decades and combines in the Unimog the experience and competence of specialists as well as the expertise of competent Unimog partners.

Product benefits

Off-road capability.

No matter the obstacles you need to overcome, the Unimog is built to master almost every imaginable obstacle.

Its engageable all-wheel drive ensures the vehicle steadily continues, even on difficult terrain. The Unimog is equipped with two features to ensure greater traction: differential locks can be engaged to prevent wheels from spinning. And the central tyre control system, TireControl plus, adjusts tyre pressure to the ground beneath the wheels. The single-tyre principle is also well thought-out: The rear wheels follow in the tracks made by the front wheels and are, therefore, able to use the firmness of the surface already compacted by them.

Unique frame concept.

Flexible and robust in operation: The key factor in the off-road ability of the Unimog U 4023 and U 5023 is the offset vehicle frame. Thanks to its torsional flexibility in combination with torque tube technology and the three-point mounting of engine, transmission, cab and body, a diagonal torsion of up to 600 mm is possible. As the frame is fully welded, it permanently withstands torsion. At the same time, the frame offset gives the vehicle a low centre of gravity with high ground clearance.

A further plus in off-road operations: Axle suspension with torque tube. By connecting the axles to the transmission using torque tube and thrust ball, axle articulation of up to 30° can be attained. And encapsulation protects the drive shaft against contamination with dust, water and other outside influences when driving off the beaten track.

High ground clearance.

The intelligent response to any challenge. The typical Unimog portal axles ensure high ground clearance but with a low centre of gravity. And the asymmetrical arrangement of the axle differentials makes it easier to drive over obstacles. The suspension mounting has been strengthened and defies even the greatest stresses and strains. The axle design is also really robust: It makes great standard load capacities possible.

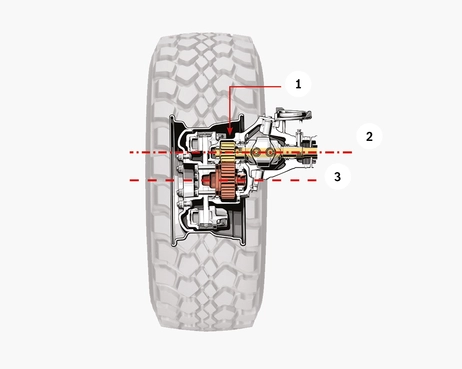

Portal axle

1 Hub reduction gear

2 Axle centre

3 Wheel centre

Steep climb.

The short frame overhang at front and rear provides wide approach/departure and breakover angles. This means: there's almost no terrain, however steep it may be, that poses a problem for the Unimog. This vehicle is equally at home in floods and in waterlogged areas: waterproofed assemblies, a vertical air-intake pipe and high vent pipes allow the Unimog to ford water depths of up to 80 cm (optionally 120 cm).

TireControl plus.

The switch logic of the tyre control system allows the user to choose between the pre-set "Road", "Sand" and "Rough" modes. This means the correct mode for the current road surface can be set intuitively, making operator error virtually impossible. TireControl also brings benefits for nature: driving off-road with lowered tyre pressure improves traction while reducing the impact on the land.

A performance that breaks records.

6,694 metres above sea level – you can't get more off-road than that. Never before has a wheeled vehicle driven at such an altitude. Matthias Jeschke and his expedition team achieved just that on 13 December 2019 with their two Unimog vehicles in Chile, breaking the world altitude record for wheeled vehicles at the time.

Unimog impresses TV presenters.

Speed. Ouput. Driving enjoyment. Jean Pierre "JP" Kraemer and Matthias Malmedie know what they're talking about when it comes to vehicles. Both have already put many vehicles through their paces on the German Mercedes-Benz YouTube channel called “Let’s drive Mercedes”. However, neither of them had ever tested a Unimog from Mercedes-Benz. And it simply leaves the professionals speechless.

Product benefits

Body variants.

The extreme off-road Unimog can work in places others cannot even get to.

The Unimog is vehicle and tool all rolled into one. The prerequisites for this are defined by the existing spaces for implement carriers, as well as interfaces and drives for fixed or interchangeable devices. The Unimog has two different transmission power take-offs and one engine PTO. A vehicle hydraulic system to power different implements and continuous consumers is available as optional equipment. Standardised sockets provide electric power. The body mounting space can be used is lots of different ways: The possibilities range from platform bodies and box bodies to special solutions for specific requirements.

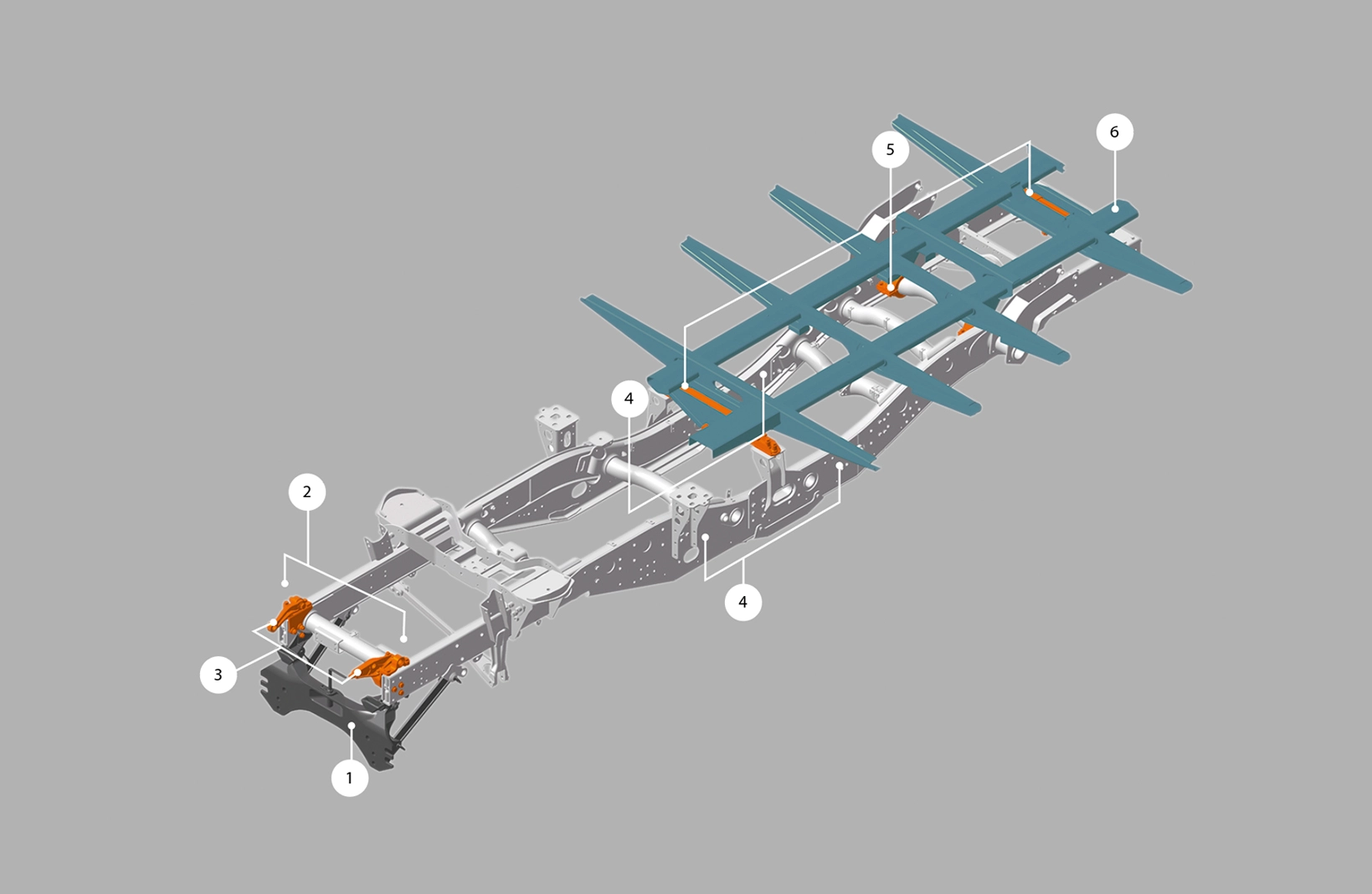

Quick implement change.

Defined mounting points make it easy and quick to switch implements and to fasten a wide range of attachments securely and safely.

1 Standardised front mounting plate for attachments up to 1.5 t

1 Front mounting brackets for compressors or units

3 Cable winch brackets

4 Frame mounting brackets

5 Mounting parts for platform bodies or box bodies

6 Floor assembly for special bodies

Powerful transmission and engine PTOs.

The engine-driven power take-off opens up a wide range of potential applications, for example for the operation of a firefighting or hydraulic pump. The proven transmission power take-offs can also be integrated into the extreme all-terrain Unimog as an option, for example a fast variant for hydraulic pumps and a very fast variant for firefighting pumps. The design of the sub-frame makes the transmission power take-offs easy to access for a wide range of potential uses.

Vehicle hydraulics and electrical interfaces.

Attachments such as cable winches, snowploughs, front loaders or hydraulic tools can be powered by the vehicle's hydraulics. The single-circuit hydraulics provide an operating pressure of 240 bar at a delivery volume of 60 l/min and 24 kW pump output. Standard sockets are positioned on the front and at the rear end. Four standard sockets are available to provide the power supply to the implements.

Product benefits

Ergonomics.

Get in, feel good, get going.

This refers to the comfortable seating position and clear vehicle settings in the instrument cluster. These characteristics contribute in no small way to greater safety and ease of operation and ensure that work and comfort go hand in hand in the Unimog. For the quicker and more intuitively users can operate the many different driving and working functions, the safer and more reliably the vehicle can be deployed off-road

Optimal working conditions: the operating concept.

People who don't just drive from A to B but who need their vehicle for tough day-to-day work have different requirements when it comes to operation and comfort.

The comfortable interior and a cockpit that has been adapted to perfectly meet users' needs together create outstanding working conditions. This leaves you free to focus all your energy on carrying out all your tasks... and to be comfortable while doing so. All controls are located within easy reach: just one way that the Unimog makes your life easier.

Ergonomic progress.

The cab assists the driver, in particular when the job needs to be done and there's little time for lengthy deliberation: Intuitive and ergonomically-located controls help to simplify operation. The seating position in the low-vibration area behind the front axle enables more comfortable off-road driving and offers a very good view of the driving area. The area being driven through is lit up by the daytime driving lights and the headlights.

Like at home.

The interior offers a high level of comfort and makes work easier. The heating and air conditioning system provides the right temperature to ensure good working conditions in every weather. The cab offers space for two full-size individual seats and the optional middle seat. The modern workplace also includes a DAB radio with Bluetooth hands-free feature. The centre stowage and the standard glove compartment look tidy so everything is clear and shipshape.

Product benefits

Safety.

You need to be a tough cookie to guarantee maximum performance in the harshest of conditions. Like the Unimog.

The Unimog is equal to the challenge thanks to its offset welded frame, thrust tube technology for extreme diagonal torsional flexibility up to 600 mm, excellent angle of approach/departure, portal axles giving a high ground clearance, all-wheel drive and differential locks, not to mention high traction and excellent gradeability. The heat protection package for fire service vehicles provides additional safety.

High-performance gearbox.

The typical Unimog gearbox takes the load off the driver and contributes to safety and comfort with practical details like Electronic Quick Reverse, off-road gear reduction and the electronic automated gearshift system, EAS.

Product benefits

Crew transport.

If you would like the Unimog to not only transport large quantities of equipment to workplaces, but also crews of up to 7 people, the crew cab is a valuable asset.

This double cab is fitted with an additional rear bench seat for four people – to comfortably seat each passenger, all secured with an individual seat belt. Four individual air-sprung seats are available as an option.

Unimog as a people carrier.

The crew cab makes it easy to get the entire team to worksites, even in extreme terrain. In addition to sufficient head- and legroom, there is also plenty of stowage space under the fold-down rear bench seat. Tools, equipment and personal belongings can be safely stowed in them and are always at hand. The front-door compartments feature further stowage options. A total of four wide-opening doors – two on each side of the vehicle – also provide ergonomic access to, and exit from, the rear passenger compartment.

High efficiency.

In the Unimog, the fully synchronised electro-pneumatic transmission with its eight forward and six reverse gears provides the tractive power. A special off-road group is also available with an additional eight forward and eight reverse gears each for low driving speeds. It is characterised by its particularly smooth running, a long service life and great efficiency. And changes in the direction of travel are speeded up by the synchronised Electronic Quick Reverse feature.

The U 5023.

Universal extreme athlete.

The U 5023 is the right choice for anyone who needs maximum off-road performance. 3.8 m wheelbase, a fording depth of up to 1.2 m, a permissible gross vehicle weight of 15.0 t and an impressive angle of approach/departure of 44°/50° make the Unimog a reliable workhorse.

Applications

Fire service.

Its off-road capability, robustness and equipment compatibility make the Unimog a reliable partner for fire services worldwide.

Numerous implements and bodies are possible, and thanks to the standardised body interfaces as well as various hydraulic and mechanical implement drives, there is a wide range of possible applications for the Unimog. From water tender, personnel transporter with crew cab, equipment and implement carriers for technical backup through to special-purpose vehicles.

Applications

Energy.

As a highly mobile vehicle built for high voltage, the Unimog is up to any challenge.

Whether for tapping into new energy sources, in open-pit mining or for the maintenance, monitoring and repair of extensive supply networks, With its great torsional flexibility, fording capability up to 1.2 metres, high gradeability of up to 45° and TireControl plus tyre pressure control system, the vehicle also masters difficult terrain.

- All-wheel drive and differential locks

- Drop tube-guided portal axles and coil springs for axle articulation of 30°

- Extreme freedom of movement thanks to large angle of approach/departure, tipping and ramp angle

- Tyre pressure control system

- Crew cab for up to seven persons

- Attachment and body interfaces as well as powerful implement drives ex factory

Applications

Off-road.

Wherever you go, you can rely on the Unimog. And therefore on high levels of reliability, robustness, unique off-road capability and high payload.

Because real adventures start where paved roads end, the Unimog can be set up as the ideal travel companion – for example, as a camper van with extreme off-road capabilities, as a robust and reliable expedition vehicle, for hunting or for rallies.

Applications

Agriculture.

Developed for agricultural use in 1946, the Unimog's traditional areas of expertise include field and agricultural work.

The implement carrier increases agricultural profitability, both on an off the farm. Interfaces as well as front and rear power lifts make this all-rounder fit for soil cultivation and crop protection, sowing and fertilising, limestone and silage transport.

Service & parts

Become

part of a legend!

We care about customer satisfaction. The Unimog is not just any old vehicle; it's an indestructible power pack, a versatile endurance runner and an adventurous all-rounder. In order to keep it at its best for many years to come, all professional Unimog users are provided with the very best support right from the start.

The Unimog is an automotive legend, in which every individual part has a role to play. Every service is decisive in how the story continues. That’s why every Mercedes-Benz Unimog service partner is more than just a workshop – it’s part of a legend. We are all part of this committed community, in which every part down to the smallest screw as well as every service appointment is crucial in making sure that the Unimog is cost effective and ready for action – empowering your Unimog to take control of everyday life with gusto – day in, day out.

Prepared to the max.

You can't put a price on reliability. When it comes to quality, costs and environmental awareness, our service providers are meeting high standards every single day. Rapid assistance with the reliable Mercedes-Benz service and genuine parts quality guarantee that your Unimog will always be ready for action.

Attractive warranty packages mean that, if any repairs do become necessary, your Unimog will be protected from unforeseeable financial risks for years to come. Meeting your needs perfectly. So that you can be fully prepared for any mission. Plan ahead now and keep the legendary Unimog running reliably: with guarantee packages that can be booked with every new vehicle purchased.

What you can expect from Mercedes-Benz.

- First-class service quality at over 650 locations in more than 130 countries worldwide

- Maintenance, diagnosis and repair

- Technical support and advice

- Advice and training tailored to requirements

- Driving, safety and technical training

- Working relationship built on partnership and fairness

Schweinfurt's Waterways and Shipping Authority in Schweinfurt has been very impressed with the Unimog's genuine parts.

As Norbert Eusemann chats with us about his Unimog, his excitement is contagious. The U 400 is the fourth model that the 57 year-old has been driving since he started working at the Volkach site of Schweinfurt's Waterways and Shipping Authority (WSA) in 1981. His passion for the Unimog was ignited when he was just eight years old and later, his passion became his profession. He is also very impressed with the service it provides. He says: "Mercedes-Benz Service has definitely earned its star."

Flexibility that gives you choices.

Benefit from the financial services solutions offered by Daimler Truck Financial Services.

With us, you can rest assured: not only our vehicles, but also our financial services are a perfect match for you. As part of Daimler Truck AG, Daimler Truck Financial Services is our in-house and fully integrated financial services provider with flexible and customer-focused solutions.

Everything from a single source.

Together with our Unimog partners, we offer tailor-made financial products from a single source. Regardless of whether you only want to use your Unimog and return it or plan to pay off the vehicle in instalments and become its owner. Get in touch with your authorised Unimog partner for more information.

Brand promise

Working for you.

As a global leader of medium-heavy and heavy trucks, Mercedes-Benz sets itself ambitious targets: we set the standard for quality and reliability. And our over 11,000-strong workforce at our modern and environmentally-friendly Wörth plant more than meet these expectations. Since 1963, over three million commercial vehicles have been manufactured here. Alongside the A-series (Actros, Arocs, Antos and Atego), all the Mercedes-Benz Special Trucks are designed and manufactured at the plant, using a good number of identical components. The fleet includes the Unimog implement carrier, the outstandingly agile off-road Unimog, the Econic and the Zetros. All models in the series are subject to the same stringent testing and trial cycles as vehicles from the large-scale production series. The Wörth plant's motto expresses our passion for commercial vehicles best: "Our mission is to get a little better each day so we can fulfil our brand pledge: trucks you can trust."

Valuable partnerships.

Mercedes-Benz has been working closely with international implement and body manufacturers for decades, combining the experience and expertise of specialists with the in-depth knowledge of competent Unimog partners. The most stringent requirements for the best system solutions.

Individualisation for manufacturer quality.

The applications possible with the Unimog implement carrier may be so specific that it might not be possible to meet series production requirements. The Mercedes-Benz plant in Molsheim is prepared for these special requests. This is where we carry out individualised production using the manufacturer's full expertise... with the manufacturer’s warranty and worldwide available service from Daimler Truck, of course!