Thanks to reinforcements made to the cab underbody and the new tubular brackets, the Unimog cab meets the ECE-R29/3 standard for cab safety and integrity.

Ready for action with any task.

Unimog is a traditional agricultural professional. Even in its early days in the 1950s, the Unimog lived up to its name at the time as a universal motorised tool for use in agriculture. It has rightly maintained its excellent reputation as an all-round talent to this very day. The Unimog can be used in a wide variety of applications with a high level of flexibility for machine use, robustness for work, strength for transportation, and safety on the road. The transport professional offers some key advantages, especially for agricultural logistics. Unimog is in use 365 days a year for farmers, contractors, and service providers.

The implement carrier.

The Unimog U 219 – U 535 is both an equipment specialist and a transport professional. Four attachment and attachment bays, a front and rear PTO, as well as powerful hydraulic systems make it obvious that the Unimog implement carrier is designed for deploying high-performance system attachments. The fuel-saving engines, high payloads, and high-speed characteristics ensure increased productivity with the growing challenges being faced by companies.

Applications

Working in fields.

In fields, it is important to be as gentle on the ground as possible – and this is no problem with the Unimog.

Unimog offers clear advantages for this application, especially for sensitive tasks such as plant protection and fertilisation. The drop centre axles ensure a high ground clearance, such as for crop protection in cereal cultivation. The tyre pressure is optimally adapted to the ground with the tyre pressure control system. This means that operation with good traction is particularly gentle on the ground, even in inclement weather conditions. Last but not least, the rear PTO enables the entire engine power to be transferred to attachments for demanding requirements, such as with large-area mowers.

Tyre-Control plus.

Unimog can be used almost anywhere and is cost-effective on a wide variety of surfaces. The TyreControl plus tyre pressure control system also ensures this. The option to choose between “Road”, “Sand” and “Bad Surface” modes means that the correct setting is automatically made at the push of a button, depending on weight and speed. The tyre pressure control system can be activated via the steering wheel – even while driving.

Bollwerk reaps his success.

The Agrio mounted sprayer transforms the Unimog into an “unbeatable work tool”, says Andreas Bollwerk. He employs only one specialist in his company, who only looks after the analysis of soil and plants and the plant protection agents required for this. His company also handles fertilisation.

“The Unimog is unbeatable.”

“The star hits me right in the chest”, says Udo Leib. The 57-year-old farmer and winemaker from Hahnheim, south of Mainz, can't hide his enthusiasm when asked about his latest big purchase, a Unimog U 529: “The Unimog is unbeatable when used with front-mounted implements.”

Applications

Agrologistics.

For agricultural use, the Unimog never comes to a halt – even when the road stops.

For farmers and contractors, Unimog is a fast and efficient transport solution in the face of ever-increasing cost pressures and larger areas that need to be covered. Because when it comes to travelling backwards and forwards between the field, the road and the unloading points, the Unimog impresses with its range of capabilties: all-terrain and gentle on the ground in the field, fast and safe on the road – and all this while accomodating high payloads and providing excellent traction. With its efficient engines, it offers particularly cost-effective fuel consumption with maximum utilisation for a wide range of agricultural activities.

High payload.

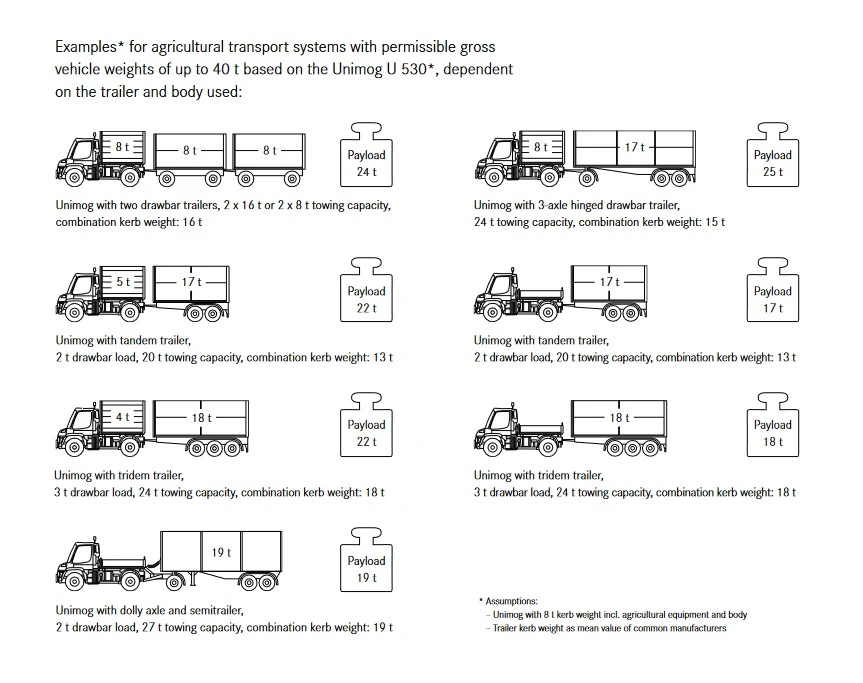

For agricultural transport, a high as possible payload is important. This is why the Unimog is designed for heavy loads and a large transport volume. With its low unladen weight for a high payload of up to 25 t with a gross traction weight of up to 40 t, Unimog offers strong arguments for its use in cost-effective agricultural logistics.

365 days on duty.

Thanks to the changing use of implements and the four attachment and mounting bays, the Unimog is not just versatile, but can also be deployed all year round – from soil cultivation to use with loading carts or trailers, from the application of fertiliser to harvesting, and from wood chipping to baling.

Ready for the motorway.

There are of course tractors specifically designed for working in fields. And there are trucks that are best suited for rapid transport on the road. And then there’s the Unimog from Mercedes-Benz. This demonstrates robust off-road handling qualities and can travel quickly and efficiently on paved roads at speeds of up to 89 km/h – making it fully suitable for driving on motorways.

Advantages with respect to approval.

The Unimog can be registered as an agricultural tractor, providing some rewarding benefits for farmers, service providers and communities, depending on state-specific requirements. The Mercedes-Benz all-rounder can therefore be exempted from taxes, tolls or even a Sunday driving ban, for example.

The Unimog compared to the tractor.

Particularly impressive: The Unimog achieved fuel savings of up to 27 %* compared to tractors in the test!

The Unimog implement carrier offers ideal conditions for contractors to make them fit for the future. Its standardised electrical, hydraulic, and mechanical interfaces enable the installation and use of all municipal implements, while the modern Mercedes-Benz drive train combines environmental friendliness and efficiency. And thanks to its maximum permissible speed of 89 km/h, the Special Truck is absolutely suited to motorway traffic.

This means that the Unimog is streets ahead of tractors, especially when it comes to its use in transportation. In a tractor comparison test, the all-rounder proved its strengths in the areas of fuel consumption, roadworthiness, payload, visibility, service friendliness, and ergonomics.

The Unimog U 427 scores points in the system comparison*:

- Lowest fuel consumption (41.3 l/100 km without trailer or 60.0 l/100 km with two trailers)

- Lowest unladen weight (9,065 kg)

- Second highest payload (4,935 kg)

- Short vehicle front (1.81 m)

- Excellent view of front attachments and traffic conditions

- Guaranteed visibility thanks to parallelwindscreen wipers, each with three water nozzles

- Easy maintenance of battery, cab filter, and powertrain

- Ergonomic working environment with completely suspended and heated co-driver’s seat

- Convenient central locking

* Tractor test 2020, Agricultural Chamber Lower Saxony, lwk-niedersachsen.de

Grascobs from the Allgäu region.

One year of Unimog U 529 under testing. At RegioGras eG in Hergatz in the district of Lindau, this means around 1,000 operating hours and around 35,000 kilometres on the speedometer. The bottom line: "No tractor can rival it for fuel consumption. Unimog has by far the lowest consumption," says Managing Director Toni Eller.

Applications

Forestry.

The Unimog is compact, powerful and efficient: a forestry worker that improves as it works.

Anyone with a need to master a broad range of tasks all year round will need a real professional. The Unimog is particularly suitable for off-road use and has excellent road handling features. From maintaining tracks in spring, maintaining woody plants in summer to chipping wood in the autumn, it can perform a range of tasks. And even in winter it can offer high levels of usability, flexibility and safety. Driving speeds of up to 89 km/h also make the Unimog the perfect transport solution for biomass or wood fuel. With three attachment bays, powerful equipment drives, high payloads and a clear-view cab, it goes to work wherever power is needed. The Unimog provides convincing advantages not only as a work machine, but also as a tractor. And it gets to its place of deployment just as quickly as it saves on fuel – thanks to its high traction, even where no track exists yet.

For those who are constantly looking for more.

As a universal professional implement carrier, the Unimog can always be the tool needed in the moment. It combines its typical power, manoeuvrability, robustness, and reliability with well thought-out details and innovations. It also works equally as naturally as a powerful tractor or crane vehicle. And in the winter season it can also be used for clearing and spreading.

Unimog has something to offer.

Rear mounting bay: For trailer loads up to 40 t gross train weight (e.g. for forestry machine transport with a low loader trailer) or 24 t plus 3 drawbar loads (e.g. for wood fuel transport). With a rear PTO, a height-adjustable trailer hitches (from Scharmüller with ball coupling 80) and rear power lift (available in different versions).

Loading and transport work.

The Unimog combines very compact dimensions with high trailer loads and payloads on its own loading area. It is therefore suitable for loading and transporting work with e.g. green cuttings, long timber or wood chips.

Using it, tasks can be carried out safely and with power both on and especially off the road. Off-road, it features other benefits such as its permanent all-wheel drive and high ground clearance. The central tyre pressure control system provides more traction on unpaved surfaces and enables driving that is gentle on the ground.

The Unimog is particularly quick and efficient in getting to its location – with speeds of up to 89 km/h, it can transport people and machines to its place of deployment – and it can also be used with heavy trailers or e.g. large chippers. This is why the Unimog is also suitable as a tractor vehicle to pull along low loader or regular trailers.

Forest and greenery maintenance.

The Unimog can be used in a variety of ways, especially for vegetation maintenance, for example with a cable winch for felling hazardous trees, pruning and hedge trimmers, rootstock cutters or mowing implements for road verge maintenance. With its switchable steering, an optimal view of the work area and stepless traction drive featuring a hydrostat, work is completed particularly efficiently.

Powerhouse for the gardening and landscaping business.

Stefan Schatz calls his gardening and landscaping business “Schatzgarten”. The creative garden landscaper has acquired a treasure with his new Unimog U 530. He and his Unimog salesman Markus Förster, RKF Bleses, have configured his “blue miracle” so that the Unimog can do almost everything required for gardening and landscaping.

Applications

Road maintenance.

Communal services can be provided particularly efficiently with the Unimog.

Unimog offers contractors in particular the opportunity to ensure additional capacity utilisation and thus additional sources of income, even outside of the harvesting seasons. The Unimog finds its leading role in winter service in particular. However, Unimog is also a reliable machine for street and path maintenance with its flexible application options and convinces with its capabilities.

Ensures clear paths.

In street and path maintenance, for example, the Unimog can handle the maintenance of watercourse paths. Or show its laurels with the simultaneous use of up to three mowing implements and one mowing trailer. To make such work even more comfortable, the Unimog can also be equipped with interchangeable steering, a rotating seat, or a mower door.

Ready for use in winter.

Spreaders from 1.5 to 4.4 m³ can be mounted on the Unimog tipping platform or directly onto the ball couplings of the ground assembly. With its narrow vehicle width from 2.15 m, it can also reach places where other vehicles would be too large. With the Unimog, ploughs and spreaders are quickly fitted ex works thanks to standardised interfaces such as the front mounting plate. This makes it ready for use even in the event of a sudden onset of winter. Thanks to its short front-end dimensions, it offers a perfect view of the road and, thanks to its balanced axle load ratio, it reliably performs its function in winter, for example through its safe driving characteristics, directional stability, permanent all-wheel drive and ABS.

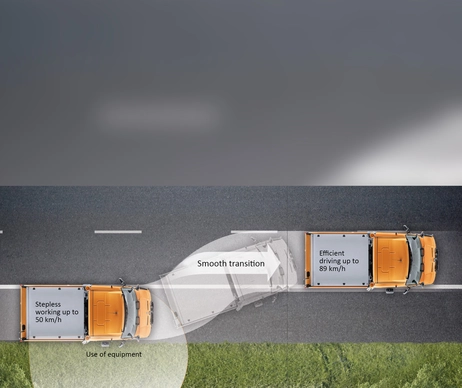

Easy Drive.

The synergistic Easy Drive traction drive combines the advantages of a fuel-saving manual gearbox with a stepless hydrostatic traction drive. The operating speed can be continuously adjusted and maintained using a cruise control function. It is easy to switch between stepless and mechanical transmission while driving.

A heart for bees.

The Landsberg district has some beautiful roads. This is ensured with the help of two Unimogs from the building yard. 200 kilometres of district roads and another 200 kilometres of municipal roads – the area of operation for the communal Unimog U 500 and the U 530 which was also purchased last autumn is impressive.

Unimog in use on the Brienz Rothorn railway.

Metre by metre, the Unimog U 430 works its way forward, with 220 kW of pure power! The snow blower at the front turns to its upper edge in glossy white. The snow flies through the spout into the air in wide arcs, rushing down the steep slope just a few metres further down.

Product benefits

The Unimog implement carrier.

Designed to work.

The Unimog implement carrier concept enables cost-effective, high-performance and, above all, efficient work. This means that even the most demanding tasks in agriculture and forestry, such as those involving wood chippers, loading carts or large area spreaders, present no problems.

- The modern cab offers safety and a high level of driving comfort, thanks to the fully-suspended chassis, the seating position behind the front axle, and the comfort seats with their integrated belts.

- All implement, hydraulic and driving functions can be conveniently controlled via a multifunctional joystick.

- Permanent all-wheel drive and 3 differential locks.

- Automatic transmission (EAS) for gearing without shifting is available as an optional extra.

- The synergistic Easy Drive traction drive enables stepless driving at speeds of up to 50 km/h under working operation and allows the driver to switch between hydrostatic and mechanical drive while driving.

- Drop centre axles.

- The short size of the front and the deep-lying panoramic window provide an optimum view of the implements attached on the front.

- In addition, the lighting package with its working and roof-mounted headlights in combination with the new windscreen wiper concept ensures perfect visibility even in difficult conditions.

- The electrically driven steering power assistance allows the steering wheel to be operated comfortably and without much effort.

- Reinforcements in the driver's cab according to ECE-R29/3 standard ensure increased safety for the occupants.

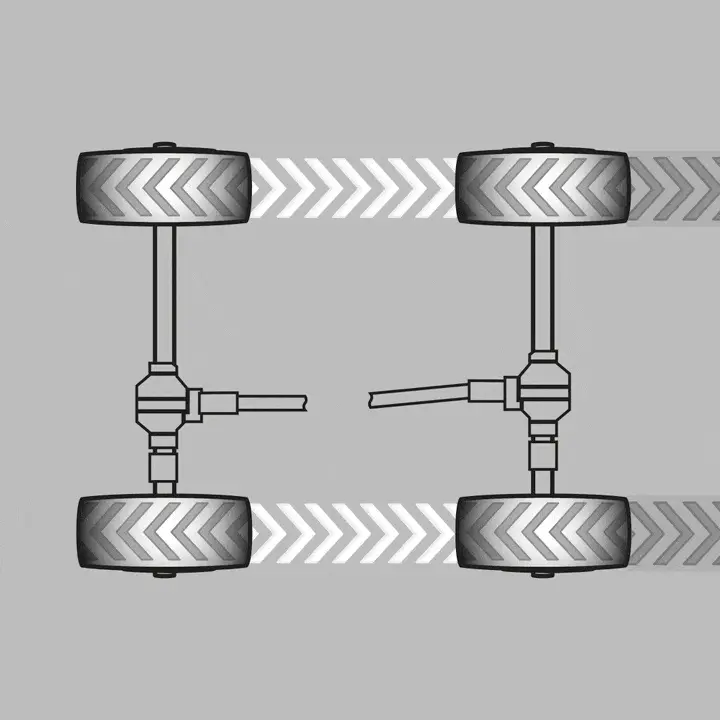

The newly designed tyre pressure control system TireControl plus is also available as an option. This is integrated within the drop centre axles, works automatically or manually, and can be easily activated from the steering wheel. Three modes can be selected for optimum traction in the field, reduced fuel consumption on the road, and good roadholding at high speeds.

- The modern cab offers safety and a high level of driving comfort, thanks to the fully-suspended chassis, the seating position behind the front axle, and the comfort seats with their integrated belts.

- All implement, hydraulic and driving functions can be conveniently controlled via a multifunctional joystick.

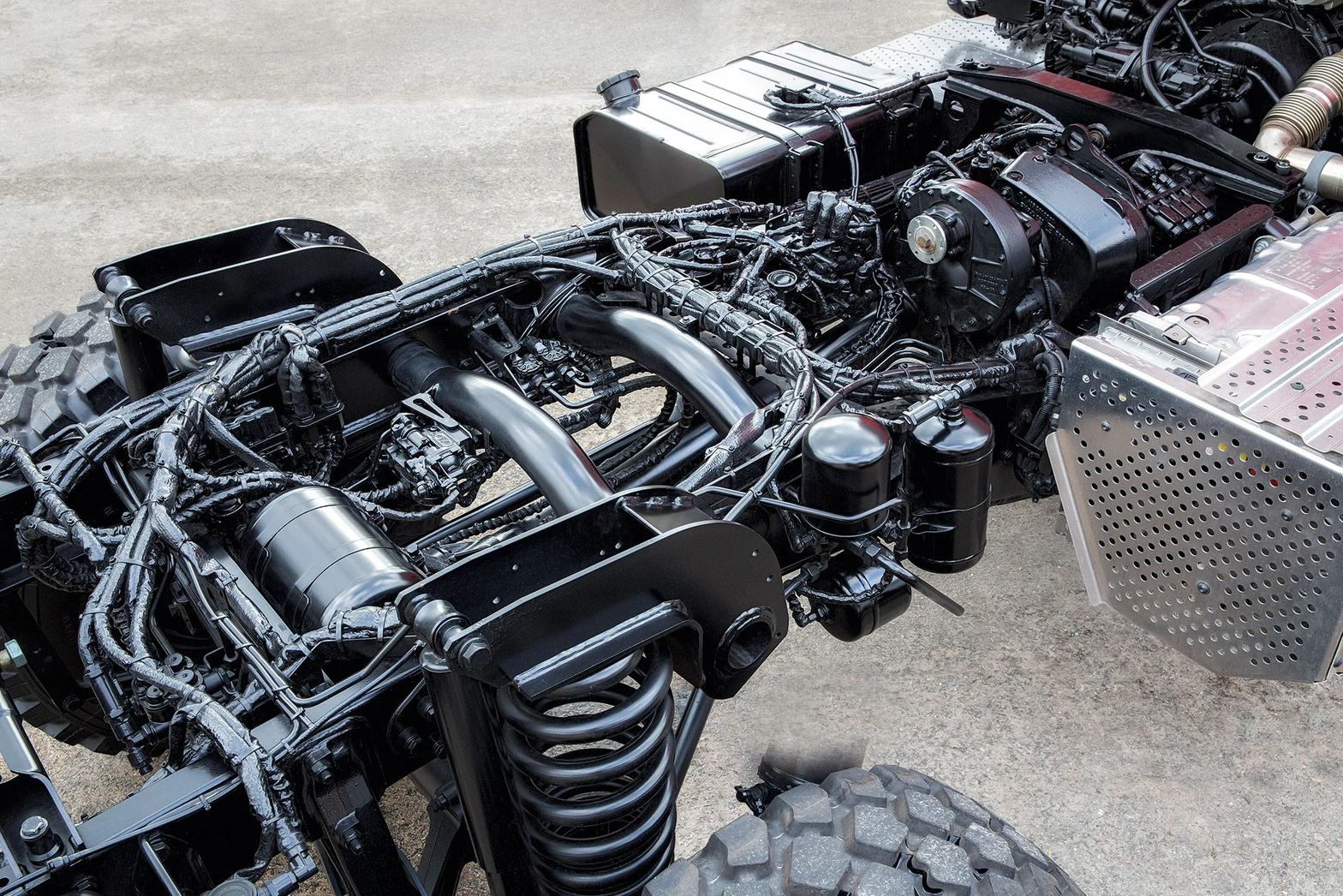

Efficient common-rail diesel engines with high performance, reduced fuel consumption, and up to 90% reduced emissions thanks to the Euro VIe technology:

- 4-cylinder with 190 and 231 hp and 750 and 900 Nm torque

- 6-cylinder with 272, 286, 299 and 354 hp and 1,100, 1,200 and 1380 Nm torque

- Permanent all-wheel drive and 3 differential locks.

- Automatic transmission (EAS) for gearing without shifting is available as an optional extra.

- The synergistic Easy Drive traction drive enables stepless driving at speeds of up to 50 km/h under working operation and allows the driver to switch between hydrostatic and mechanical drive while driving.

- Drop centre axles.

The front PTO produces 160 kW and the mechanical rear PTO can transmit the full engine power.

- The short size of the front and the deep-lying panoramic window provide an optimum view of the implements attached on the front.

- In addition, the lighting package with its working and roof-mounted headlights in combination with the new windscreen wiper concept ensures perfect visibility even in difficult conditions.

- The electrically driven steering power assistance allows the steering wheel to be operated comfortably and without much effort.

- Reinforcements in the driver's cab according to ECE-R29/3 standard ensure increased safety for the occupants.

- Front and rear power lifts and front mounting plate.

- The tipping platform can be supplied with a shelf.

- Standardised interfaces.

- 4 double-acting hydraulic control devices.

The newly designed tyre pressure control system TireControl plus is also available as an option. This is integrated within the drop centre axles, works automatically or manually, and can be easily activated from the steering wheel. Three modes can be selected for optimum traction in the field, reduced fuel consumption on the road, and good roadholding at high speeds.

Depending on the application, high-studded or road tyres are available with steel or aluminium rims. A maximum tyre size of 495/70 R 24 is available for the U 530 in high-studded form.

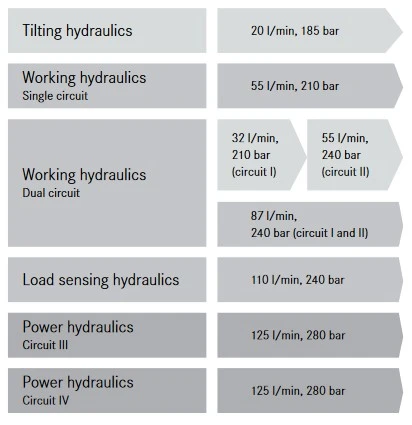

Various hydraulic systems are available depending on requirements, such as the load-sensing hydraulic system with up to 110 l/min hydraulic oil flow and operation at 240 bar pressure: powerful and fuel-saving at the same time.

Cab.

No matter what the day brings and what task lies ahead of you: The open-view cab of the Unimog implement carrier fulfils high standards with regard to operation, comfort and safety. Features include intuitive and ergonomic operation as well as the comfortable seating position, pneumatically-suspended comfort seats with 3-point belts, head restraints and seat heating, standing heating and air conditioning. ABS and the 3-point equipped cab also contribute to improved ergonomics and driving comfort. The cab with its panoramic glazing offers either 2 or 3 fully-fledged single seats as well as an optimum view of the areas being worked on.

Vario-Pilot® variable steering.

For an optimum overview of the driving and working area at the same time, the Unimog features the practical VarioPilot® interchangeable steering as an option. This allows the driver to change the seating position to the other side of the vehicle depending on the deployment.

In combination with the optionally available glass mower door, an ideal view of the working implements is guaranteed while mowing or maintaining verges.

Right/left variable steering:

- Change of the steering wheel position including the instrument panel and pedals in less than 30 s

- Optimal seating position for every deployment

- Assists one-man operation and improves cost-effectiveness, especially during work involving mowing and turning

Tyre-Control plus.

Unimog can be used almost anywhere and is cost-effective on a wide variety of surfaces. The TyreControl plus tyre pressure control system also ensures this. The option to choose between “Road”, “Sand” and “Bad Surface” modes means that the correct setting is automatically made at the push of a button, depending on weight and speed. Nature also benefits from this: Driving off-road with reduced tyre pressure improves traction while at the same time protecting the ground.

Overview of benefits.

- High transport speed of up to 89 km/h.

- Efficient transportation thanks to its high payload.

- Low fuel consumption.

- Efficient Euro VI engines.

- As a tractor approved for forestry and agriculture it is not subject to tolls or Sunday driving bans.

- Options to deploy with front and rear mountings using a hydraulic system and PTO shafts ex works.

- All the conventional agricultural mountable implements can be operated.

- Comfortable driving and off-road capability as a result of its chassis concept.

- Compact dimensions for greater manoeuvrability when things get a bit tight.

- High versatility through communal and agricultural deployment (transport and equipment).

Product benefits

The extreme off-roader Unimog.

For working in the field and in communal applications: The Unimog extreme off-roader is just ideal.

With its all-wheel drive and torsional flexibility, it masters every challenge and is always clearly the leader in rough terrain: For protecting vegetation, it offers high ground clearance in the field as well as speed on the road. Equipped with communal hydraulics and a front mounting plate, various implements and attachments can be mounted, such as snow ploughs and spreaders for use in the winter. A loading crane can also be used to carry out various transport and handling tasks.

- Tyre pressure control system TireControl plus.

- All-wheel drive for high traction.

- High ground clearance due to its drop centre axles.

- Differential locks.

- Short frame overhangs for extreme slope and ramp angles.

- Off-road gear reduction up to 100% to enable climbing.

- Torsionally flexible vehicle frame.

- Suitable for fording up to 1.20 m.

- Fully-suspended chassis and cab.

- It has a large radiator in the protected area above the front bumper.

- Fully welded frame and encapsulated drive train for a long service life when used on difficult terrain.

- Powerful engine rated at 170 kW (231 hp).

- High payload.

- Engine PTO as a mechanical interface for an implement drive (600 Nm), transmission PTOs and hydraulic pumps.

- Driving speed up to 89 km/h.

- Tyre pressure control system TireControl plus.

- All-wheel drive for high traction.

- High ground clearance due to its drop centre axles.

- Differential locks.

- Short frame overhangs for extreme slope and ramp angles.

- Off-road gear reduction up to 100% to enable climbing.

- Torsionally flexible vehicle frame.

- Suitable for fording up to 1.20 m.

- Front camera for extending the field of vision.

- Reversing camera.

- Modern and comfortable driver’s cab.

Extreme off-road capability.

The extreme off-roader Unimog is a genuine off-road professional. Its high ground clearance is enabled by its drop centre axles, which allow it to smoothly overcome obstacles. The wheel transmission is protected against dust and dirt. The Unimog’s extreme torsional flexibility is based on its torsionally flexible frame: All wheels are in constant contact with the ground. The chassis enables a large axle articulation of up to 30° thanks to the thrust-tube technology and coil springs, as well as a minimum stress load on the body due to the doubled three-point mounting. The cab and body can be twisted by up to 12° relative to one another. Uncompromising all-wheel drive, differential locks and constant maximum traction also contribute to the extreme off-road capability.

Fording capability up to 1.2 m.

The drive technology of the Unimog extreme off-roader is arranged so that water depths of up to 0.8 m or up to 1.2 m if selected can be driven through. In addition, the Unimog has waterproof main headlights, central high ventilation and a double sealing on the wheel hub. The catalytic converter and raised exhaust make the vehicle fully suited to fording.

Tyre-Control plus.

The switch logic of the tyre pressure control system allows the user to choose between the three preconfigured modes “Road”, “Sand” and “Bad Surface”. This means that a correct setting can be set intuitively for the respective surface. Nature also benefits from TireControl plus: Driving off-road with reduced tyre pressure improves traction while at the same time protecting the ground.

Implement use.

An advantage when used with front-mounted devices is the front mounting plate for attaching a snowplough, earth bulldozer or front-mounted sweeper for deployment in disasters. In addition, the Unimog is also equipped ex works with hydraulics for cable winch operation (60 l/min). The cable winch holder for a self-recovery winch is integrated in the front attachment. One transmission PTO is specially designed for operating a fire extinguisher pump.

The U 200 series.

U 219

Expert implement-carrying system for service providers and local authorities.

The U 219 is the smallest Unimog model with an extremely short wheelbase of just 2.8 mm. This makes it able to work in all those places where every millimetre counts. With its 140 kW (190 hp) engine, the U 219 model has enough power for almost any challenge that comes its way. Plus, it offers three different load values ranging from 7.5 to 10 t and so is well-equipped for a whole host of tasks.

The U 300 series.

U 319 | U 323 | U 327

High endurance for small and medium-sized towns.

With an engine output of 130 kW (177 hp) and a gross weight of 11 t, the U 319 reliably meets all the important municipal requirements. Together with the special models U 323 (170 kW/231 hp) and U 327 (200 kW/272 hp) with a permissible gross weight of up to 14 t, this model series fits the bill for everything for which an entire fleet would otherwise often be required.

The U 400 series.

U 423 | U 427 | U 430 | U 435

Versatile top performers.

If you're a Unimog user who moves heavy loads works on a wide range of jobs, the U 423 – U 435 models with gross vehicle weights from 11.99 t to 14.0 t are perfect for you! All four are available with either a short or a long wheelbase. The main differences are in their engine performance. This can be 170, 200, 220 or 260 kW (231, 272, 299 or 354 hp).

The U 500 series.

U 527 | U 530 | U 535

There's no obstacle it can't overcome.

Giving everything you need all year round yet still having power reserves to hand – this is what the 500 models with 200, 220 or 260 kW output (272, 299 or 354 hp) are all about. And with their gross vehicle weight of maximum 16.5 t, they can both shoulder heavy loads too. The wheelbases are 3.35 or 3.9 m (long version), the longest in the range.

Service & parts

Become

part of a legend!

We care about customer satisfaction. The Unimog is not just any old vehicle, it's an indestructible power pack, a versatile endurance runner and an adventurous all-rounder. In order to keep it at its best for many years to come, all professional Unimog users are provided with the very best support right from the start.

The Unimog is an automotive legend, in which every individual part has a role to play. Every service is decisive in how the story continues. That’s why every Mercedes-Benz Unimog service partner is more than just a workshop – it’s part of a legend. We are all part of this committed community, in which every part down to the smallest screw as well as every service appointment is crucial in making sure that the Unimog is cost effective and ready for action – empowering your Unimog to master everyday life with gusto – day in, day out.

Schweinfurt's Waterways and Shipping Authority in Schweinfurt has been very impressed with the Unimog's genuine parts.

As Norbert Eusemann chats with us about his Unimog, his excitement is contagious. The U 400 is the fourth model that the 57 year-old has been driving since he started working at the Volkach site of Schweinfurt's Waterways and Shipping Authority (WSA) in 1981. His passion for the Unimog was ignited when he was just eight years old and later, his passion became his profession. He is also very impressed with the service it provides. He says: "Mercedes-Benz Service has definitely earned its star."