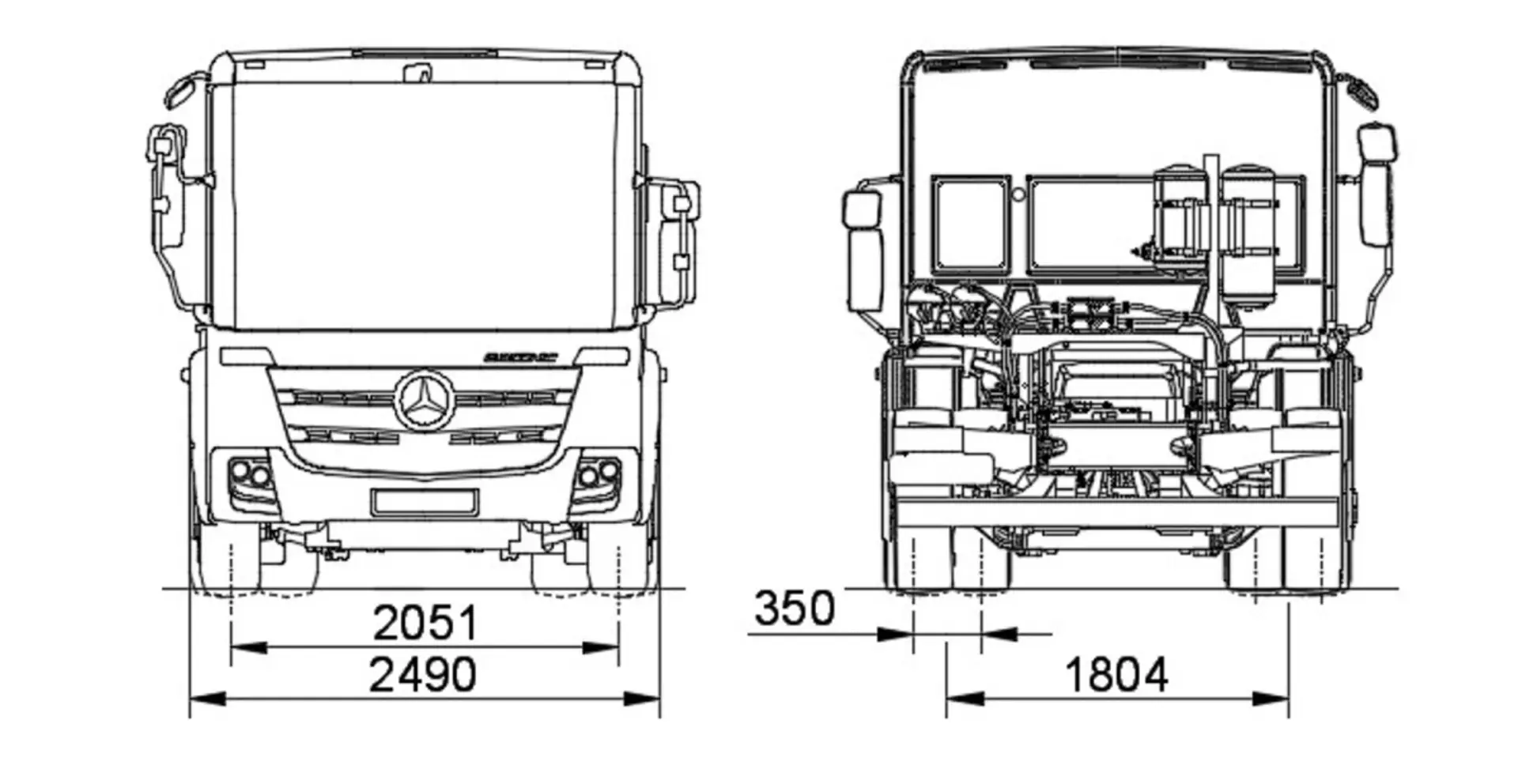

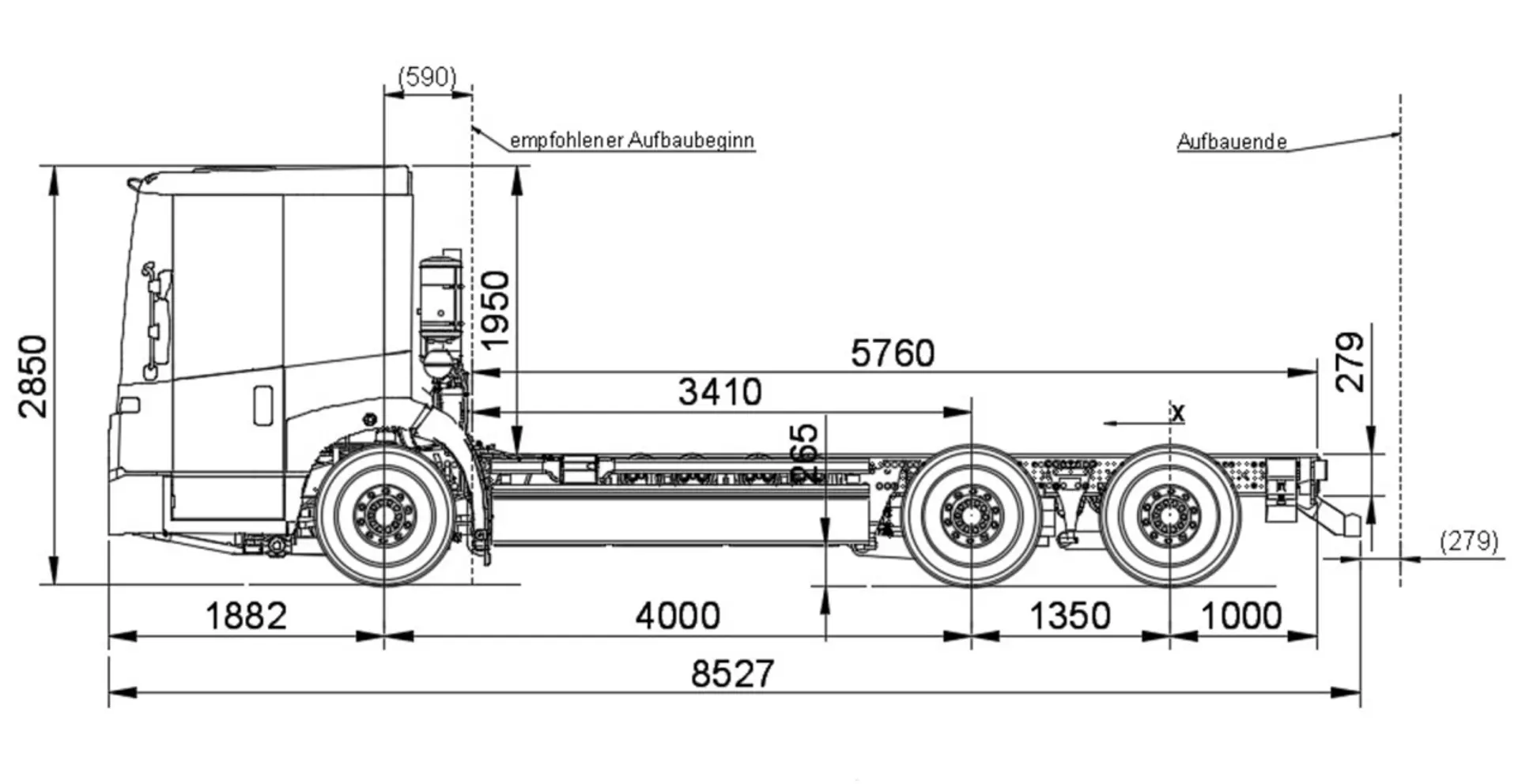

| Type | e300 6x2/4 | e300 4x2 |

|---|---|---|

| Max. Vehicle length (mm) | 8,527 | 7,178 |

| Vehicle width (mm) | 2,490 | 2,490 |

| Vehicle height (mm) | 2,850**** | 2,850**** |

| Type | 956.533/956.534 | 956.503/956.507 |

| Wheel formula | 6x2/4 ENA | 4x2 |

| Wheelbase (mm) | 4.000/4.200 | 4.000/5.500 |

| Unladen weight (t) | 9.2 | 8.1 |

| Gross vehicle weight (t) | 27 | 19 |

| Payload without body (t) | approx. 17.7 | approx. 10.9 |

| Cab | Low-entry cab with flat cab floor | Low-entry cab with flat cab floor |

| Axle load [air suspension] (t) | 8.0/11.5/7.5 (+ optional 8.0/12.0/8.0) | 8.0/11.5 (+ optional 8.0/12.0) |

| Engine power [max./cont.] (kW) | 400/330 | 400/330 |

| ePTO High Power [max./cont.] (kW) | ~52/~30 at 50 % SOC | |

| Max. Speed [km/h] | 89 | 89 |

| Transmission | 2 gears (+ 2 reverse gears) | 2 gears (+ 2 reverse gears) |

| Batteries | Lithium-ion | Lithium-ion |

| Number of battery packs | 3 | 3 |

| Range (km) | up to 100/150* | |

| Installed battery capacity (kWh) | 336** with three battery packs | 336** with three battery packs |

| Charging power (kW) | max. 160 | max. 160 |

| Charging time (min) | approx. 75*** (from 20 to 80%) | approx. 75*** (from 20 to 80%) |

* The specified range is provisional and was determined on the basis of an internal simulation tool assuming optimum conditions, including with 3 new battery packs after preconditioning in a partially loaded state in inner-city refuse collection operations (VECTO Municipal Cycle up to 100 km) or in mixed refuse collection operations (combined from VECTO Municipal Cycle, VECTO Regional Delivery and VECTO Urban Delivery Cycle up to 150 km) at 20 °C outside temperature, and may deviate from the values determined in accordance with Regulation (EU) 2017/2400. Among other things, the actual range depends heavily on the handling, usage profile and type of body.

** Nominal capacity of a new battery, based on internally defined framework conditions. This may vary depending on the application and ambient conditions.

*** The eEconic can be charged with up to 160 kW: Based on internally determined empirical values, the three battery packs require just over one hour to be charged from 20 to 80 % under optimal conditions, including an ambient temperature of 20 °C at a standard DC fast charging pole with 400 A charging current.

**** The vehicle height depends on the tyres.

Subject to change without notice. Specifications are to be regarded as approximate. The illustrations may also include accessories and special equipment that are not part of the standard scope of delivery, as well as types and support services that are not offered in individual countries. Statements on statutory, legal and tax regulations and effects are only valid for the Federal Republic of Germany. Therefore, please ask your Mercedes-Benz commercial vehicle sales representative for the latest binding status.

Series.

- Low-entry: low entry and exit with only 2 steps:

- 1st step: 450 mm on Econic 4 × 2 and 6 × 2/4 from outside into the cab with standard tires 315/60 R22.5

- 2nd step: 350 mm in the driver's cab (access height increased by 190 mm)

- Staircase-shaped arrangement of steps

- Cab made of aluminum profile frame (space cage)

- Cladding made of SMC plastic parts

- Step-through cab floor

- Comfortable headroom in standard cab 1,935 mm

- 4-point cab suspension

- Panoramic glazing and low parapet

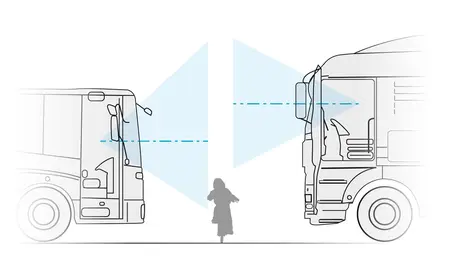

- Low seating position at eye level with passers-by

- Coated, tinted and heated Thermocontrol windshield of the panoramic glazing prevents fogging of the windows - for an even clearer view of the traffic scene

- Electrically operated full-length sunblind over the windshield

- Power windows

- Revolving driver's door with power window

- Grab handle on driver's door

- Inward-opening, fully glazed, pneumatic folding door on passenger side (on standard cab)

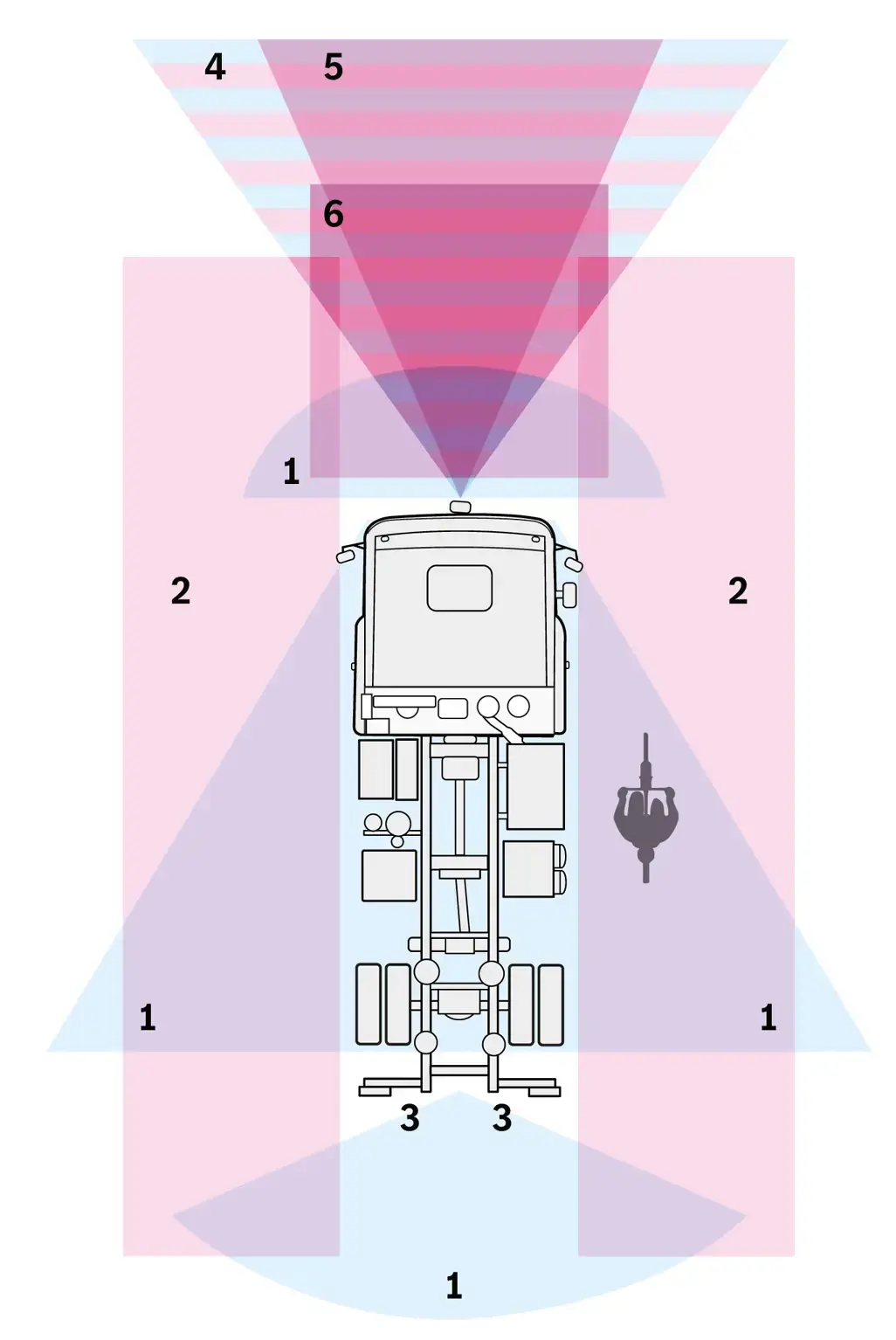

- Mirror system to extend field of vision to work and blind spot areas

- Roof hatch/ventilation flap roof

Series.

- Shock-absorbing full air suspension

- Level cab floor ensures comfortable, safe access and therefore exit on the side away from traffic

- Side headroom in standard cab 1,920 mm

- Driver swing seat, standard

- 3 passenger seats, static, with head restraints

- Seat concept with different seat heights

- Roof hatch

- Several storage compartments, bottle and cup holders

- Coat hooks on the rear wall of the driver's cab

- Pollen filter in the air intake of the vehicle ventilation system

- 2 remote control keys

- Multimedia cockpit, interactive incl. Bluetooth mobile phone connection and use of Android Auto and AppleCarPlay

- Opening and closing of folding door via control button in switch panel

- Control switch active for a short time even after ignition is switched off

- External control switch can be switched off from inside the vehicle

- Powerful heating and ventilation system

- Air conditioning

- Multifunction steering wheel, height and tilt adjustable

- Lifting and lowering function of the vehicle on all axles

- Tuck Data Center

- Tachograph, digital

Special equipment

- Driver swing seat, comfort

- 1 or 2 passenger seats

- 1 or 2 comfort passenger seats

- Imitation leather seat cover

- Instrument cluster, 12.7 cm, with video function

- Tachograph, 1 day and 2 drivers, modular

- Parameterization working time with ignition off

- Seat belt reminder, driver and passenger side

- Digital radio

Command center in the eEconic.

The driver is continuously supplied with e-relevant information, for example the charge status of the batteries, the remaining range, and the current and average energy consumption. The control system for superstructures can also be easily integrated into the cockpit - allowing the driver to control important functions directly from the cab.

* The specified range is provisional and was determined on the basis of an internal simulation tool assuming optimum conditions, including with 3 new battery packs after preconditioning in a partially loaded state in inner-city refuse collection operations (VECTO Municipal Cycle up to 100 km) or in mixed refuse collection operations (combined from VECTO Municipal Cycle, VECTO Regional Delivery and VECTO Urban Delivery Cycle up to 150 km) at 20 °C outside temperature. The range is strongly dependent on driving behavior, the application profile and the type of body, among other factors.

Equipment

Brakes.

The eEconic focuses on high road safety and short braking distances by transmitting very high braking torques to the brake discs, which can withstand high thermal loads. Compared with conventional drum brakes, the Special Truck with its self-adjusting, internally ventilated floating caliper disc brakes also achieves a payload gain through lower weight.

Series.

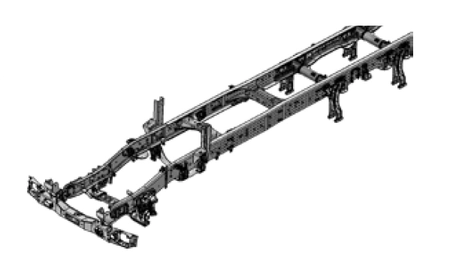

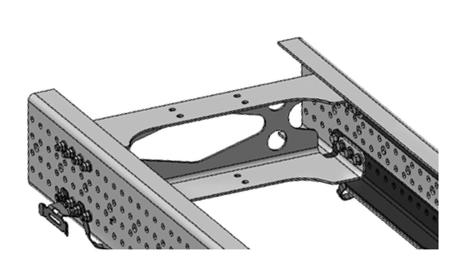

- Frame with continuous hole pattern, longitudinal member's distance between holes 50 mm, 4-row

- Diverse implement mounting and anchorage options

- Frame overhang ex works, 1,000 mm

- End crossmember screwed on the side, can be moved from 650 mm to 1000 mm in 50 mm grid without any changes to the chassis

- Standard front axle 8.0 t, offset axle housing, weight-optimised

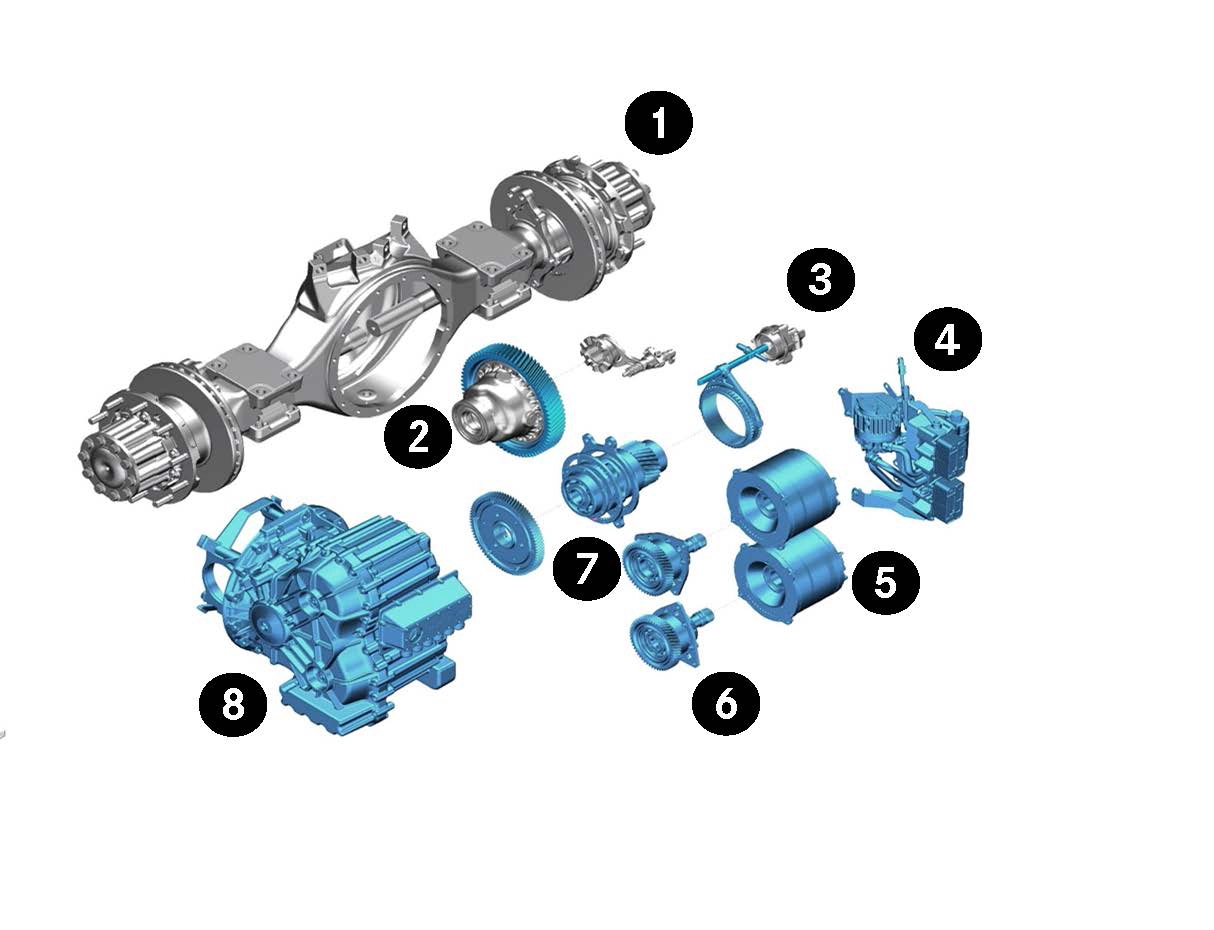

- Driven rear axle 13.0 t, planetary hub reduction axle with crown gear 300 mm (on 6x4 driven rear axles 13.0 t, planetary hub reduction axles with crown gear 233 mm)

- Rear axle(s) differential lock

- Air suspension on all axles (rear axle via 4-bellows air suspension), height adjustment up to +160 mm or –40 mm depending on variant via lifting/lowering procedure (e.g. lifting vehicle at disposal site)

- Long rear axle ratio, i = 6.824

- Axle load measuring device

- Electrohydraulically steered leading or trailing axle with 7.5 t load capacity, relievable (not liftable), not driven

Optional equipment.

- Body interface behind cab

- Electrical interfaces between vehicle and body

- Power supply for implements up to max. 50 A

- Speed and distance signals C3/C4

- Switching PTOs on/off

- Interface for connecting an external (device-side)

- engine remote control for start/stop, speed change

- Actuation of transmission for crane body or waste disposal vehicles (e.g. speed limitation, immobiliser)

- Free lines routed into the cab for use as required by the bodybuilder

- Signals for activated rotating beacon and rear reversing lights

- Actuation of 3 free control lights in the instrument cluster

- Pre-installation for work lamp incl. switch

- Lowered frame as an option for single-tyred steered trailing axle, with residual bellows pressure control for tipper bodies

- Axle ratio i = 6.000

- Simply implemented weight-optimised 13 t sheet-steel formed axle with 44 mm crown gear

- Trailing axle, 8 t, steered, relievable

| Power constant/max. 300/400 kW | |

|---|---|

| Voltage | 350 V |

| Torque (const./max.) | 31,000 Nm/39,000 Nm |

| Number of gears | 2 (2 forward/2 reverse) |

| Gear ratio | l = 46/15.03 |

| Starting capacity (5x/5 min.) | 12 % |

| Vmax | 89 km/h |

| Vmin @ 3 % gradient | 80 km/h |

| Max. Braking power (recuperation) (kW) | 330 kW/400 kW (max.) |

| Capacity (t) | Total train weight 40 t |

| Weight | 835 kg |

Series.

- Vehicle power supply 24 V

- 4 kw starter power

- 2,800 W (28 V/100 A) alternator

- Low-maintenance 2 × 12 V/170 Ah battery

- Trailer socket, 24 V, 15-pin

- On-board socket 24 V/15 A

- Electronic vehicle management system with diagnostic interface and on-board diagnosis

- CAN bus network

- Starting-off aid, time limit 90 s

Lighting:

- LED headlights

- Dipped beam

- Main beam

- Side lights

- Daytime running lamps

- Pre-installation for rotating beacons

Optional equipment.

- 4,200 W (28 V/150 A) alternator

- 2 × 12 V/220 Ah battery

- Additional socket 24 V/15 A, dashboard console

- Additional socket 12 V/15 A, dashboard console

- Interface, FMS 2.0 Fleet Management System

- Moving-off aids (with/without time limit or speed limitation 30 km/h)

- Reversing warning device

- Electrical interfaces for bodybuilders

- Battery master switch

- Trailer socket, 24 V, 15-pin

Lighting:

- Halogen headlamps

- Work lamp manoeuvring assistance

- Automatic activation of hazard warning lamp

- Rotating LED beacon

- Pre-installation for LED turn signal lamps at the rear

- Cable set extended by 2 m for the vehicle tail lights